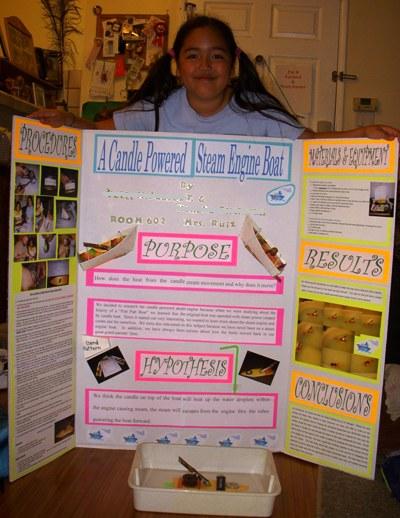

Though relatively simple construction (no moving parts, unless you count the deflection of the bottom of the boiler), putt putt engines ingeniously harness several principles of physics to push the boat and make raucous boat noises. And instead of just ejecting the water until the boiler is dry--as intuition seems to tell us it should be-- the water keeps coming back in a continuously repeating cycle. Understanding the cycle uses all of Newton's laws of motion.

Tip 1: Water expands a lot when it turns to steam.

Most people know this, but did you know steam can occupy more than a thousand times more volume than the water it came from? If it is prevented from expanding, it builds up pressure instead. That's what happens with popcorn, which ideally has a 14% moisture content inside. The hard shell keeps the bit of moisture contained. The steam pressure builds until the kernel explodes. If it has dried out to 9% moisture, you can hardly pop it. Interestingly, putt putt boats are sometimes called "pop pop" boats.

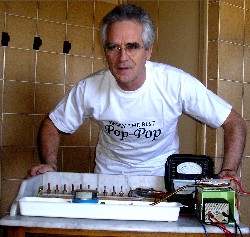

Most people know this, but did you know steam can occupy more than a thousand times more volume than the water it came from? If it is prevented from expanding, it builds up pressure instead. That's what happens with popcorn, which ideally has a 14% moisture content inside. The hard shell keeps the bit of moisture contained. The steam pressure builds until the kernel explodes. If it has dried out to 9% moisture, you can hardly pop it. Interestingly, putt putt boats are sometimes called "pop pop" boats.

Both popcorn and the putt putt engines employ violent expansions of steam, yet both are pretty safe because such a small amount of water is involved. Don't ever try to bake an unopened coconut in the oven, though!

If you put a spoonful or two of water in a ziplock bag (or any plastic bag that can be sealed) and heat it in a microwave oven, you can see how the steam occupies many times more volume than the water it came from. It can't explode because the plastic becomes so soft it can't contain any pressure. Balloons with bit of water and tied also work.

Phase 1:

Explosive, expansion.

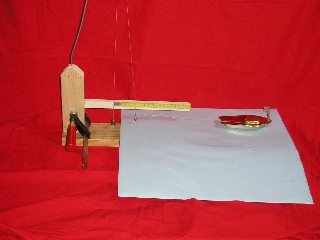

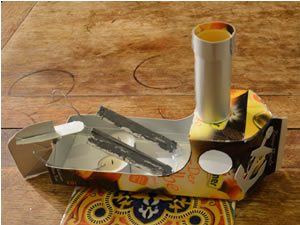

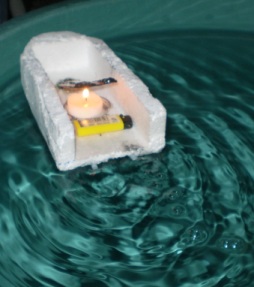

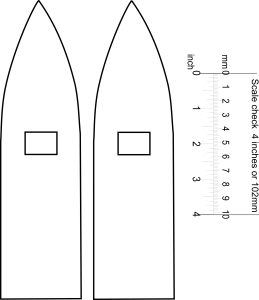

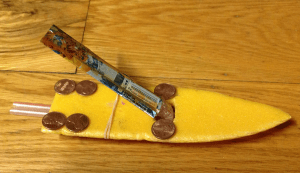

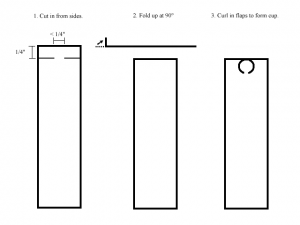

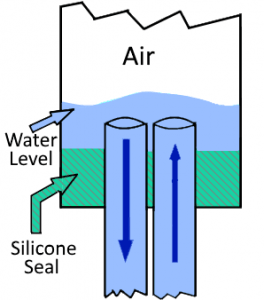

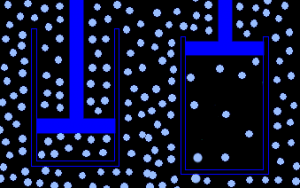

Let's first establish that the aluminum boiler does not fill full with water. Tilting the boiler to prime it makes the boiler stand up in such a way as to fill the straws and just a bit of the bottom of the boiler. If you had x-ray vision, you would see that when you prime the engine with water, the water comes in one straw and runs back out the other straw without putting much water in the aluminum boiler. This is as it should be. The "wetting" step deposited tiny droplets of water on the inside walls of the boiler. Once the aluminum is heated, even the tiny candle can flash boil those small droplets of water almost instantly, and they expand enough to run the engine.

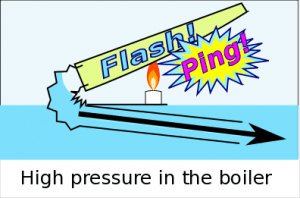

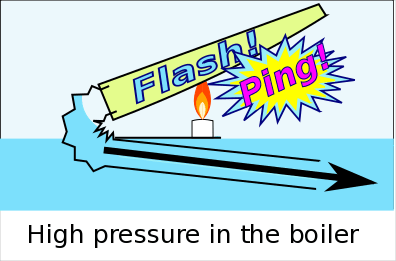

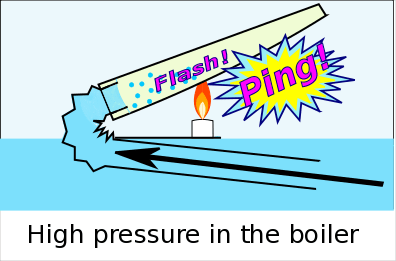

Two things happen as the droplets flash explosively into steam: The bottom of the boiler pushes out with a ping. And the the water in the straws is pushed out.

If you measured the pressure inside the boiler, it would be higher than atmospheric pressure

Tip #2: A moving water column has momentum.

Sir Isaac Newton's First Law of Motion states that things in motion tend to stay in motion until something stops them. Even if you turn off the engine of a moving train, momentum alone can keep it going for miles.

A moving column of water in a pipe also has momentum, just like a train. When a column of water is suddenly stopped --as when someone closes a valve abruptly-- the momentum of the water is transferred to the plumbing. It can make noise or even tear plumbing loose. Hydraulic engineers and plumbers call this phenomenon"water hammer". It was more common on older plumbing before fixtures were designed to minimize it.

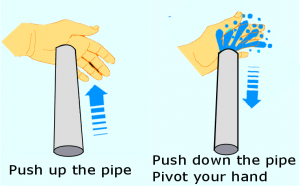

You can make a crude water pump that works because of the momentum of a water column. You need only your hands and a pipe. The pipe can be any diameter that you can seal one end of with the palm of your hand and it can't have holes or cracks in it. I have used the rigid metal extension of a vacuum cleaner that connects the flexible hose with the inlet attachment. A cheap PVC pipe around 1" or so is perfect. It should be at least a few feet long.

With at least 2 feet of the bottom of the pipe in water, cover and seal the top opening with the palm of your hand. Quickly jerk the pipe up. With the top sealed, the water in the pipe will lift up with the pipe. After the pipe has gone up a foot or so, jerk the pipe back down, while at the same time pivoting your hand to open up the top.

Back to the steam engine, the fast-moving water columns in the straws has momentum. That momentum tends to make the water want to charge ahead even when the boiler is no longer pushing it. That's good! It gives the engines an instability that keeps the cycles repeating over and over.

Tip 3: When steam condenses, it leaves a void.

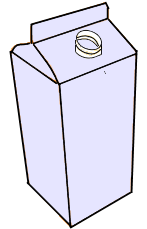

I know this sort of an obvious corollary of tip #1, but when most people think of condensation, they think of water droplets on the glass of an iced drink. The following demonstration is far more dramatic. Take one of those 1/2 gallon orange juice cartons with the screw-on lid and put a small amount of water (1/2" inch at the bottom, or several tablespoons). Put the carton in a microwave oven (you'll probably have to put it on its side) but do not put the lid on yet!!! If you put the lid on tightly now, the carton will explode. Set the power on high. The idea is to get the water inside boiling, then keep it boiling for about a minute. When it has--carefully so you don't get burned--take the carton out of the microwave and screw the lid on all the way.

The carton is now filled with steam. You can just let it condense slowly, but it's really dramatic if you spray the carton with cold water. Atmospheric pressure--about 14 pounds per square inch--easily crushes the carton.

Phase 2:

Rarified, momentous expansion.

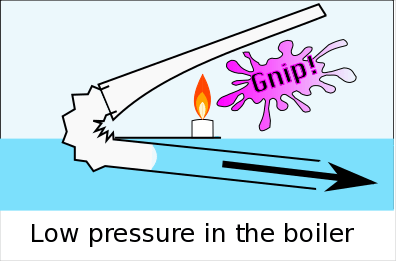

Although the water is still jetting out the ends of the straws because of momentum, the situation inside the boiler is very different from phase 1. The boiler is dry, no longer generating steam pressure because the water droplets have boiled off into steam. The column of water in the straws is no longer being pushed. But the momentum of the exiting water in the pipes keeps it going outward. Behind it --inside the boiler-- it expands the amount of volume available to the fixed amount of air inside. This creates a lower-than-atmospheric pressure inside the boiler. Colloquially, people call this a "vacuum", which isn't really right because there is still air in there, just less of it. "Rarified atmosphere" is a better term, I think. Whatever you call it, it's a huge change from phase 1, when there was high pressure in the boiler!

The bottom of the boiler bulges inward (concave), again making a sound (I called it "gnip" ('ping" spelled backward) in the illustration).

Phase 3:

Spring-back contraction.

We could say that the suction inside the boiler is now trying to pull the water column in the straws back into the boiler. More accurately, we should say say that normal atmospheric pressure is pushing the water back in. In any case, the water's momentum has been pushing against the air pressure. When the water's momentum is finally gone, the air pressure springs it back toward the engine. Some of the water squirts back into the aluminum boiler. Remember, that boiler was dry in phase 2. The candle has still been heating the metal, though, so the droplets of water explode into steam. There is high steam pressure in the boiler, again pushing out the water, and so on. The cycle repeats several times per second until the candle burns out.

Lingering question 1:

Why doesn't the boat go backward in reaction to the water column returning toward the engine?

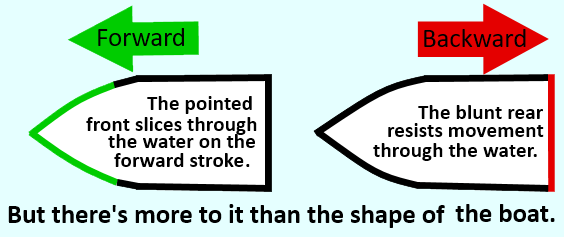

Sir Isaac Newton's Third Law of Motion is the familiar, "For every action there is an equal and opposite reaction." This is what propels jets and rockets--even in the deep vacuum of space. So, when the water jets backward out of the straws (action) the boat jumps forward (reaction). OK so far. But then the water rushes back into the straws, which would suggest the boat should actually kick backward in reaction. Why doesn't the putt putt boat just shake forward and backward in the water and not really go anywhere?

For years I assumed the whole answer lay in the shape of the boat. The pointed front cut forward through the water, while the blunt square back of the boat resisted going backward, sort of a hydraulic ratchet. But when I actually put it to the test--mounting engines on square boats, or even backward on pointed boats-- the engine still chugged forward. Clearly, some other principle is at work here.

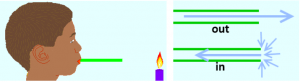

I am speculating that the answer lies in the different way the water exits and enters the ends of the straws. Consider this: If you blow through a straw, you can blow out a candle from more than a foot away. But if you suck in the air, you have to be within an inch or two of the flame to blow it out (I am not suggesting you breath fire to try this out). This leads me to think that in the first case, much of the air keeps going straight when blown out. But in the second case, air enters the straw from all angles --not just in front. If we then apply Newton's Third Law, most of the reactions cancel each other out in the second case.

However, Dr. Jeff Bindon explains it another way, and I am unable to find a flaw in his reasoning. He uses this analogy to illustrate why sucking water into the engine does not cancel out the expulsion phase:

Imagine a man standing at the front of the flat deck of a small boat. He starts to run across the deck towards the back and as he accelerates, he exerts a force on the deck and the boat is propelled forwards. He continues to accelerate and exert a force until he comes to the end of the deck and leaps into the water. The boat is now moving and as it does so, it passes another man in the water and he grabs hold of the ladder at the back of the boat. The boat jerks him into motion and the boat is slowed slightly. He climbs onto the deck and proceeds to accelerate and run towards the front of the boat. He exerts a force on the deck and the boat is retarded. But he does not want to leap off the front of the boat so he decelerates and exerts a propulsive force on the deck. By the time he has stopped, the propulsive force he has exerted is exactly equal to the retarding force he initially exerted. Or you can argue that he walks slowly to the front of the boat and exerts no force when he starts or stops. So, a series of men floating in the water, climbing on board, running and jumping back into the water can propel a boat !!

Lingering question 2:

Why doesn't the glue sealing the engine burn?

Although the putt putt engine is the most challenging project on this site, it would be even harder if you had to solder it together, as is the traditional way to make them. Furthermore, most solder does not stick to aluminum, so you would have to find special brass sheets instead.

It is not a good idea to run the engine dry, but when water is in, it stays below the temperature that would damage the epoxy and silicone. Consider that a water balloon can be held above a lit candle without bursting. The water keeps the rubber cool.

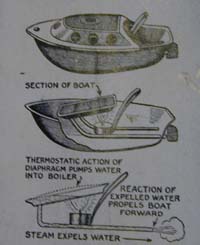

Another interesting thing is the timing of the patent application: 1934. The illustration on the right is from a science publication of 1933 featuring a toy boat manufactured and imported from Japan. You can see a

Another interesting thing is the timing of the patent application: 1934. The illustration on the right is from a science publication of 1933 featuring a toy boat manufactured and imported from Japan. You can see a