Here are some tips to make better boats.

Candle holders

Two people have sent in brilliant alternatives to the candle holder in the video.

Mark Quinn’s design uses leftover aluminum from the can. His words verbatim below the pictures:

Hi. I have been building a putt putt boat from the instructions on your web site with my niece and I came up with a quick and easy candle holder for the engine.

Back in part 8 (step 5) a template was placed on the folded aluminum and used to trim it. This cuts off two strips of aluminum, one used later to work epoxy into the engine, and a spare scrap. The spare scrap I had was almost an inch wide (24 mm actually).

I had to straighten the strip, because it was part of a round can. I did this easily by pinching the strip between my thumb and forefinger and sliding them down the length of the strip a couple of times, being careful not to cut myself with the edge.

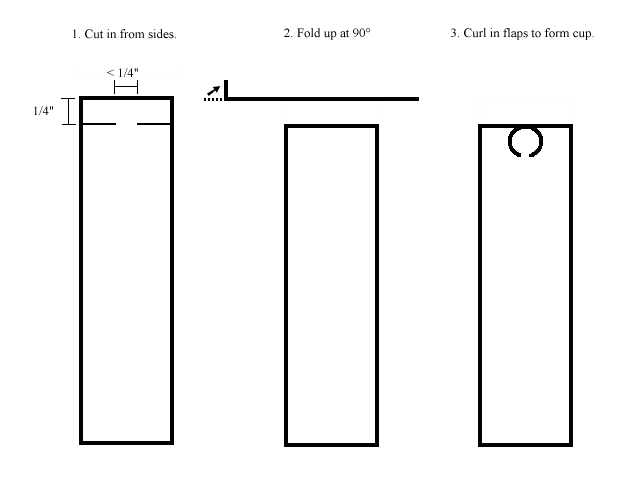

About a quarter inch from the end of the strip I cut in from the sides, leaving about a little less than a quarter inch of metal in the middle.

Then I folded the strip up where I had cut it 90°.

The cuts create two flaps. All I had to do was curl them back to form a cup. I curled the flaps into a circle smaller than the size of the candle. This allowed the metal to grip the candle slightly. The flaps do not need to form a full circle to hold the candle.

Give this a try and see how it works. I hope this is useful to you.

An Oil Burner

The first boats I saw in Bangladesh had little oil lamps that buned vegetable oil. Dustin came up with a great DIY design. Even his introduction is clear, so I’ll just hand it over to him.

A Three Dimensional Styrofoam Hull

John Neyberg sent me these pictures of a 3D foam hulll. Foam can also be cut with electrically heated nichrome wire. The steps in his own words:

1) I came up with the hall design by using the print out hull for the flat Styrofoam plan from https://sciencetoymaker.org/ and taping it to a 2″ piece of construction insulation board.

2) I ruff cut the outside of the hall and sanded it by taking a 60 grit piece of sand paper down to my table to smooth it out.

3) When I got real close I changed to 100 grit to get a nice smooth finish. Then rounded the corners by holding the sand paper in my hand and curling it to the shape I wanted.(I suggest leaving the bottom flat for stability.)

4) For the inside edge I used a sharpie felt tip and carefully using the out side edge as a guide with my finger I drew a line around the top edge about 1/2″ from the edge. (note the ink will have a chemical reaction with the Styrofoam and cause it to melt a little so you have to be real careful where you put it.)

5) The inside is a little tricky. A dremel helps if you got one I used a small routing bit to ruff cut the outline on the inside.(You can do it with a straight edge razor if your careful.)

6) Then to hollow it out I used a straight edge and cut lines front to back and side to side and dug the unwanted material out with my thumb nail being careful not to get to close to the lines or the outside and bottom.

7) I took my 60 grit and smoothed the inside down to about 1/4″

8) Then I used two 1/2 ounce lead fishing sinkers to add weight one in the bow and one in the stern hot gluing them with the boat in the water to get perfect balance.

9) Then I cut the hole in the bottom where the plan shows by aligning it up with the stern of the boat.

10) I hot glued the boiler straws to the bottom with a couple of drops in front and back.(rubber bands work too)

11) I made the candle holder out of a can and cut and bent it to make a rudder that hangs over the stern.

12) Then using the plan again I cut out a deck from flat Styrofoam for the bow, and the stern of the plan became a windshield sanding them to fit snug with out gluing them so they can be removed for installing a new boiler or working on it.(this will add support to the model for big clumsy hands)

Sciencetoymaker Home Putt Putt/Pop Pop Boat Home