Note: This article was originally published in January 2005.

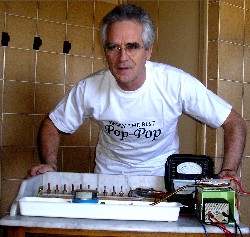

Dr. Flogel is famous for his conversions of Dutch wooden shoes into pop pop boats!

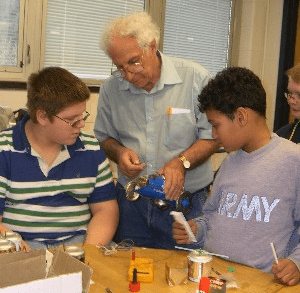

The following letters and pictures were sent to me when we were first corresponding and just getting to know each other. I have reprinted the letters as it was, since they convey wonderful European charm. Further down the page see his Dutch wooden shoe boat and his (tongue-in-cheek) explanation! Dr. Flogel has become a great friend--actually visiting my home in Pennsylvania and coming into my school for two whole days and teaching. My students and I had a wonderful time!

Dear Slater,

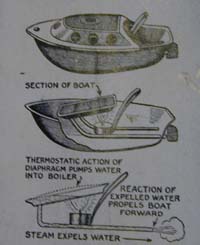

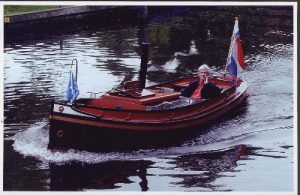

Thank you for your answer. I do not have a picture of my pop pop boat at the moment, but this time I will try to send you one of my antique tugboat. In fact it isn't only a boat for tugging, but mainly for pushing. In our language the are called 'opdrukker'. Is there a name for it in your language? Probably not, because in the literature I found these little boats were developed and used only-in the northern part of Holland in the period 1920-1930. In that time the cargo ships were almost all sailing vessels. They experienced heavy competition by the first generation of motor driven cargo ships. After a lot of failing attempts to find an answer to this threat, finally these boat proved to be the adequate answer. They boats were approximately 6 m long. They were simply attached with ropes to the stern-post of the cargo vessel in case of no wind or the impassability to head against the wind. They operated unmanned. They were handled from the the cargo vessel by ropes. Nowadays these boat are of course not used any longer for there original purpose, but those remaining after all these years are all in hands of fans or museums who are restoring them and using them for fun. In the beginning, the boats were powered by an old automobile engine. Later, when the building became more professional, by a diesel engine. Most boat are looking more or less like the little boat on your web site. They gave a disproportionately high deck-house. My boat however, was built as an open boat. Some years later they covered the engine as you will see on the picture by a very low deck. The engine is a 1 cylinder two stroke diesel. Normally, the combustion by a diesel is caused by the high compression in the cylinder head when the piston moves upward. This engine is a predecessor of the diesel as we know it nowadays, but the compression of this old type is very low. To start the engine the owner had to heat the cylinder head with a blowtorch for --depending on the temperature-- around approx. 7 minutes. Then he had to turn vigorously the huge flywheel in the reverse direction.By this action it was impossible to pass the compression, so he had to release it Then the flywheel was pushes back like a spring by the compression caused by his action and with a certain amount of luck, the engine started to run.

The sonority of the sound of the engine is beautiful and from far people know it that I am coming, long before they can see me. The funny thing is that the frequency of the diesel has a range between 120- 400 rev./min. I bought the boat 13 year ago. She was in a desolate condition. It to several years to restore her. There is a association of tugboat and push boat owners in our country. Each year we see each other at the national meeting somewhere in the country. In 2001 my boat became the 'opdrukker of the year', a prize for the best restored specimen.

Best wishes, Guus Flogel.

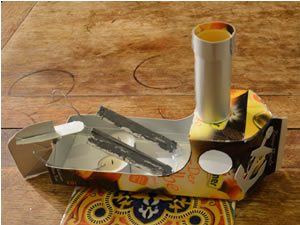

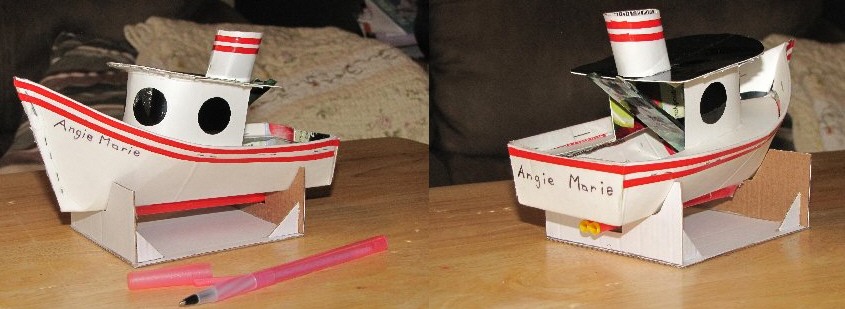

He added this note and a picture of a really well-made pop pop boat.

Dear Slater,

Hereby, it's OK with me if you want to use the pictures of my antique tugboat or recently made boat on your site.

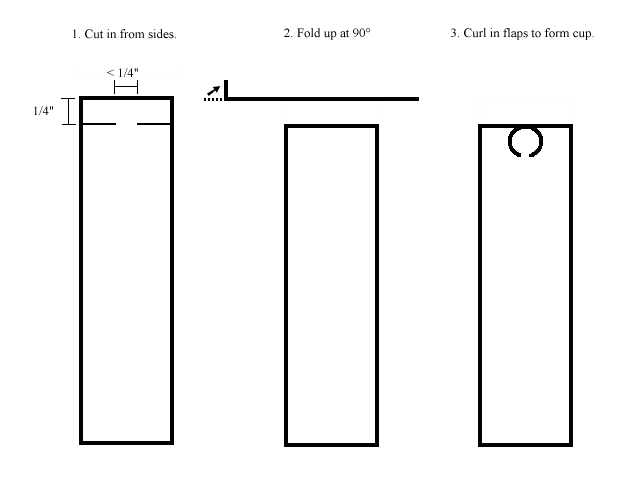

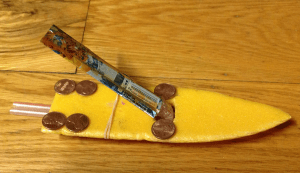

Hereby I send you an example of one of my replicas of your design.

Next year May is again the yearly meeting of the National Dutch Tugboat Society (more than 225 members) These meetings last 3 full days and are very popular. Mostly the are at least 200 big tugboats and approx. 20 tugboats of my size. Each year we welcome thousands of visitors. I have joined this meetings at least 5 or 6 times. This year I have the intention to take a couple pop pop boats with me and an inflatable bathtub for children to give demonstrations for the members and the public. I am almost sure that this will attract a lot of interested people. Probably this will lead to a club of pop pop boat fans. I will let you know by that time what happened.

Sincerely yours, Guus Flogel.

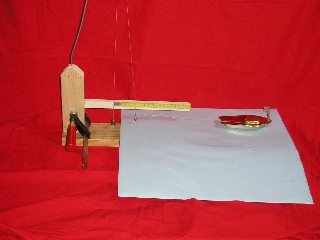

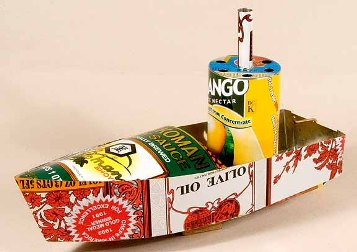

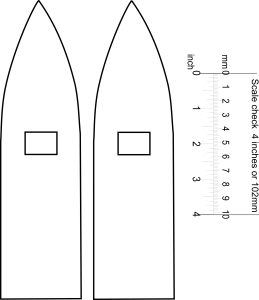

Here is the latest from Dr. Flogel: a Dutch wooden shoe powered by a pop pop engine!

Hi Slater,

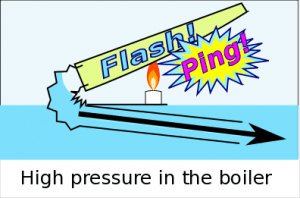

Hereby I send you the promised pictures of my typical Dutch sailing wooden shoe. Some of them are driven by a pop pop engine of your design, some have the good old spiral engine*. I used the spiral engine because it is rather difficult to build an engine in a wooden shoe. So I tried this because they seemed very reliable to me. No risk of a burn-out. So I took the disadvantage of much less power from them.To my surprise the speed of the spiral engines driven boats is comparable the wooden shoe's with a pop pop engine. The vessels are of course not as hot-tempered as our small light-weight boats. They move resolute but majestic trough the water. They need more heat however than the pop pop engines. A candle doesn't work. I use an alcohol burner with a wick of almost 2 mm. diameter. The alcohol tank contents 5 - 6 cc alcohol. That is enough for 3/4 to 1 one hour running.

In contrary to the pop engines, spiral engines lack the sound of an old fashioned diesel engine. They are completely noiseless.

I like the sound of pop pop boat, but the mysterious silence of the spiral engine has unmistakable his charms. Did you ever make a trip on a real steamboat? It's impressive. The boat moves trough the water like any other boat, but you can hear from the engine absolutely nothing!

It is the experience of the quite, past times of the beginning of the 20th century.

My best wishes, Guus

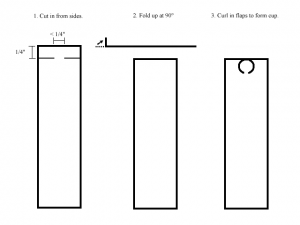

*the pipe has a diameter of 3 mm . The spiral has a diameter of apporox. 11/2 cm. I tried engines with 3,4 or 5 spirals. The one with three performed better than the others.

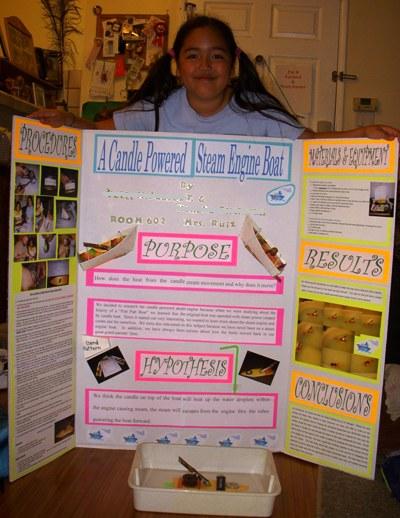

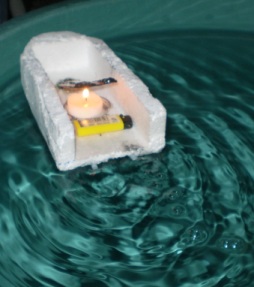

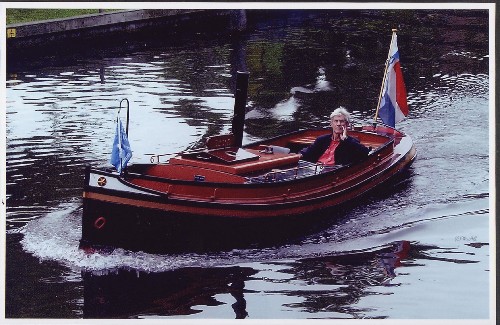

Finally, this tongue-in-cheek solution to global warming!

Dear Slater,

The legend of this picture is:. The inventor is testing the seaworthiness of the steam shoe. This picture was placed by an article I wrote over the danger of the steady rise of the sea level as the result of the greenhouse effect, with the risk that 50% of the country will be inundated in the future. As you probably know 1/2 of our country lays 5-6 m below sea level. And some experts say the defense of our dikes and dunes are insufficient in the future.

To save the people of our country I advised to produce millions of wooden shoes, who are, in contrary to leather shoes, absolutely waterproof. In the forepart of each shoe a little pop pop engine has to be fitted. In this way you get the double power and beside dry, the feet are kept warm by the candle . In the future every Dutchman will become so to say a human catamaran. Walking will be unnecessary. Light your the candles and the only thing you have to do is to steer with your feet. This was my main theme during our demonstrations on the National tugboat festival. Most people were amused, but some took it seriously!

As I told you, your boats, as well as Jeff's engines were demonstrated. Lots of people were interested in your engine and boat design. As I expected this I had an instruction papers available how to go to your site and a suggestion to come to the festival next year with self-made pop pop boats. I am curious if you will get response.

With kind regard, Guus