The text on this page corresponds to the instructional video about how to build Eco-Empirical Dragonfly Helicopters. The numbers correspond to numbers in the videos. Although much of the text is the same as video narration, you will also find more detail here that did not fit into the video. These parts are enclosed in brackets [like this].

Introduction

1.) Hi, It’s Slater, the sciencetoymaker. In this video you’ll find instructions for making a flying machine that will go higher than the tallest trees.

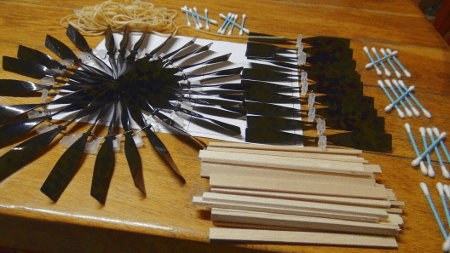

2.) You can build it with a kit that includes such things as model airplane rubber bands, which store far more energy than regular office bands. ( We no longer sell the kits. Read Update).

1.) (Sorry, wrong numbering in the video) These tools will help you:

- A “low-temperature” hot-glue gun (the small, cheap 10 watt hobby kind),

- tape,

- needle-nose pliers and

- scissors.

- A single-edge razor is helpful but optional.

You’ll also need

- a 2-liter drink bottle for making your own propeller;

and for the body, either

- straws or food packaging foam. [It could be foam grocery trays that vegetables and meats/poultry come in; or takeout trays. It can even be made out of bamboo skewers or anything else that’s strong and lightweight. The video goes into this more].

And by far the most important thing is your attention and time. With some experience you might make a helicopter in 10 or 15 minutes; but this first time, when everything’s new, allow at least an hour of following directions. Experiment… after you get yours flying.

3.) There’s some amazing science to explore when you build your own helicopter, especially Sir Isaac Newton’s 3 Laws of Motion and the ocean of air that is the troposphere we live in. Because you can adjust the propeller angle, you can experiment with crazy things like flying the Dragonfly upside down. [I have created a PDF, linked here , about some of the science involved with helicopters. Sometime I hope to make it into a video].

4.) If you want a wind-up helicopter that’s much faster to make and easier to make with younger kids, then check out this design that uses an already-made propeller. It doesn’t go as high, but it’s quick and easy.

5.) So,what if you don’t want to buy anything—even if it’s inexpensive? We’ll cover some tips for making a basic helicopter just with stuff lying around the house. [I am ok with people not buying the kit. However, I think it’s a huge mistake to not use rubber band that is made for models because they store many times more energy than office rubber bands].

6.) If any thing isn't clear, remember there is a linked web page with lots more details, and feel free to contact if you have any questions. [I am happy to answer questions, both general and help if you are stuck on something. Feedback from people like you is very important for me to know what is clear and what needs more explaining. I will put questions and answers on this page.]

[Making the Build Go Faster: If you do some steps ahead of time, then you can save time later. For example, it is more efficient for one person to cut all of the red hose pieces in one go than it is for each person to cut off some. If you do not want students to handle a razor, you might want to cut all the swab sticks and cut the slots with the razor ahead of time.]

Let's Get Started!

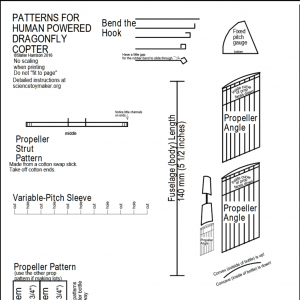

7.) Link to Pattern PDF [Although a pattern page is included in kits—and you could photocopy that—you will probably want to print out more pattern PDFs. It is important to do this with no scaling. You should be able to print out the pattern on either 8 ½” by 11 or A4 printer paper. If you have trouble printing on A4 please send feedback to me so I can correct the problem. How you get it to print out with no scaling depends on whether you are printing from a browser (and which browser) or PDF reader. Go for settings like “100%” or “full size”.

Avoid settings like “fit to page” or “shrink to fit” or any scaling except “100%”. It’s easy to know if it printed OK. Just put a ruler up to the ruler printed on the page and see if it is to scale. If you have problems with printing the correct, again, please contact me and we can try several things to get it right.]

Straighten the aluminum wire if necessary. If you printed out the PDF pattern, now is a good time to make sure that it printed to scale.

Make The Hub

8.) Cut off a 5 cm piece of the aluminum alloy wire. Aluminum is softer than steel so you can use scissors. [Steel wire should be cut with the wire cutters (needle nose pliers usually have a place for cutting wire) because it can nick the scissors. But thin copper and aluminum wires are soft enough to cut with scissors. More than ok, its actually better to use scissors to cut the aluminum wire in this case. Wire cutters (especially if they are dull) tend to mash the wire’s end a little, which makes it hard to thread on the little beads (bearings) in a later step.]

Grab the very end with the very tip of the needle nose pliers. Not part way into the pliers and not sticking out. Flush. Bend 90 degrees, pushing at the wire right next to the pliers so that's a sharp bend. Here’s a side view. If you do it right, it should be close to this pattern. [I think that I made it clear in the video, but it is much better to make sharp bends. When the wire is more rounded, sometimes the rubber band “climbs” out of the hook when wound. It is very strange, and I have not figured out why it does that. But the whole problem is avoided if you apply pressure close so the bend is sharp].

Push the tip of the pliers against the first bend, and bend 90 degrees again, always applying force close for a sharp bend. Bend yet again and you have an offset square. Make it a centered diamond, like this. Grab here inside and bend 45 degrees. This wire is the propeller shaft. Don’t lose it! [It is not a good idea to try to straighten a sharp bend. Usually the wire will break. There is some extra wire included in the kit, but not enough if lots of people break their first one.]

9.) Take the cotton off the swab stick by twisting at the end of the swab. Unfortunately, some are tightly wound and very difficult to get off, but I’ve been experimenting. Dipping in water makes the cotton easier to remove. Dipping in hot water is even better. [The hotter the water is, the more it seems to relax the cotton fibers, so it’s easier to get off. I use really hot water if I have a lot of sticks to deal with.]

[I get some strange looks when I buy a thousand swab sticks at a time. One guy even said, “I guess you have a lot of earwax!” With the first batch of sticks, it was quite easy to twist the cotton off. But when I bought another batch, I was horrified to discover that it was very difficult to remove the cotton. Panic! I was very relieved to find that wetting them makes it much easier to get the cotton off; and hot water even more so.]

[Cotton is mostly cellulose; it’s fibers similar to paper. In fact, some of the most expensive paper has cotton fibers added.]

[Cotton swab sticks are a marvel of material science and engineering! The polypropylene that it’s made from is strong and lightweight. Those qualities are enhanced by the cylindrical shape, which is known to engineers to provide lots of rigidity with a minimum amount of material. Furthermore, polypropylene has a “low friction coefficient” (is slippery) so it makes a good bearing. ]

Look close and notice the tiny channels melted into the ends that helped keep the cotton on, because they will matter in a later step. [These bumpy ends provide just the right amount of friction when stuck in the red nylon tubing, to be adjustable.]

Center the stick on the pattern; mark to get a 13 mm section in the middle; and equal length pieces on the sides. Cut straight across; NOT at a slant. Don’t lose these!

Slide this small section on the wire shaft. Slide two of these tiny seed beads on next, to reduce friction [these are low-friction bearings]. It’s really easy to lose these!

Make Variable Pitch

10.) Hold this red tubing on the pattern—if possible, with the concave, inside curve on the bottom. With the end lined up with the pattern, make two marks. Cut off on the second line. [if working with groups you can save a lot of time by cutting these ahead of time; maybe punch the hole, too].

Use the push tack to punch a hole at the mark in the middle. [It’s a good idea to back it up with some cardboard or foam so the tack does not go into the table]

Push the wire shaft--with all the other stuff on it—through in the same direction that the tack went through. [it’s just easier to get it on that way]

11.) We need a bit of wiggle room, so we’ll slide the red thing so the stick goes to the hook; then grab the wire with the very tip of the needle nose pliers. Push the wire over, applying pressure close to the pliers, for a sharp 90-degree bend. The space created by the plier tips gave us our wiggle room. Push it together and wrap a piece of tape tightly around several times. Cut off the extra wire and tape.

Remember the tiny channels at the end? That bumpy end needs to go in the red sleeve because the little grooves provide just the right amount of friction for adjusting. [it does not matter what angle at this time] [hold close to the end so the swab stick doesn’t bend] It should spin freely.

12.) I’ll use a green bottle for the propeller blades—it might show up on camera better. If you’re just making one, use this pattern—lengthwise like this. But if you’re making lots, use this bulk pattern. Cut near the ends. [The pattern has to fit so it’s only on the wide, cylindrical part of the bottle. ]

There might be a bump that rings the bottle, right where the widest part starts at the bottom; line up the edge there. [If there are two, use the one closest to the bottom. ][The objective here is to get all of the actual propeller pattern on the cylindrical part of the bottle, not the rounded parts at the top and bottom.]

Rough-cut the bottle, starting the cut with a razor. [When cutting the propeller blades by cutting on the pattern, cut by the numbers. 1 cuts the narrow strip; 2 cuts in the middle (but the tape still holds the pattern in place); 3 cuts the other end (and the paper pattern falls off).]

13.) We’ll flatten and split the strut end for strength.

[There’s a place in needle nose pliers that’s flat and about a centimeter [3/8”] across.]

Put the stick into the flat of the pliers, flush with the other side, and squeeze hard to flatten the end.

It’s dangerous to cut toward fingers; so wrap a rag around so your fingers are out of the way of the razor. Make 2 cuts at the bends, splitting into two flattish flaps. There’s an alternate method with scissors if you are dead-set against using a razor. [I used to use hot glue to stick the blades to the sticks (struts). It worked sort of ok, but the hot glue sometimes warped the plastic. And sometimes in cold weather the glue would fail. Now that I use the split end and tape, there are no troubles.]

The propeller attaches in the middle and goes straight. [Place the top of the tape even with the top of the stick.]

The top of the tape lines up with the top of the strut. If you put the tape on gently at first, then you can adjust it straight before sticking on hard. Tape the other side, too.

Cut off extra, and cut off triangles of tape, corner to stick. The outside corners are sharp, but just cut a tiny bit off.

14.) If you want to pre-adjust the blades now, the wire is below; the concave, inside curve faces down; then the blade that’s close to you tilts the right side up about 22 degrees from horizontal, or use the gauge. [There is a more detailed explanation later in the video]

A little air should make it turn like a windmill now, but don’t clock the person next to you.

15.) This is the mother of all rubber bands. From one end, cut a piece 28 cm or 11”—which happens to be the length of North American printer paper. [A piece of 8 ½ by 11 printer paper—the long way—is a fast way to measure it. But A4 paper is longer. Use sharp scissors to cut. Nonstick scissors (Teflon coated) work especially well]

Tying is easy, but confusing the first time. The overhand is the simplest knot there is—just make a loop and put the end through. But we put the two ends together and treat them like one strand. [By the way, mountain climbers know this as the European Death Knot!]

So here goes: rubber band ends together, loop, ends through. Pull a little tighter, gently.

Now we need to move the knot to the end. Hold inside the loop, right next to the knot, and pull. The knot actually moves toward the end. This does not work with regular rubber bands, but this special stuff for model airplanes is amazing.

Make The Fuselage (Body)

Fuselage 1 : Straws

16.) You can make the fuselage out of just about anything: recycled foam trays, drinking straws, bamboo skewers, etc. as long as there is space for the hook to spin.

We’ll start with plastic straws because they are ubiquitous [everywhere] throughout the world.

Measure the long, not-bendy part of two straws to about 14 cm, although it’s ok if there is some bendy part on the end. Tape the ends together.

Whatever you use, the propeller shaft has to be spaced about 3 mm away from the body so that hook has room to turn without rubbing. I glued this one on without a spacer… and the propeller cannot turn freely [because the hook rubs]. Fortunately, remember you can always re-melt hot glue with the tip. Make sure that you are using one of the lower-temperature guns. [cheap, low-temp, 10 watts]

So this time we’ll cut off a square of the spacer material. Glue it onto the not-bendy end of the straws like this. Tack on the hub so that some sticks out on both sides. Then cover it with a thin layer of glue. Spreading a thin layer of glue makes a strong connection, but making a thick blob just adds too much weight. It’s really important to not get glue on the ends, where it could rub against the wire. If glue does get on, find a way to get it off. [A thin layer of glue spread all around holds everything together. A thick layer does not add strength and would just add more weight.]

The rubber band hooks on the front, the knot always goes on the back.

We’ll make a back hook from part of another swab stick.It’s a good idea to slant the stick slightly back so the rubber band doesn’t fall off. Spread a thin glue layer for strength. The knot always goes in the back. [Use part of another cotton swab stick for the back hook. The rubber band hooks here so the back hook goes on this side, too. Because the rubber band will be pulling toward the front, I like to lean the stick slightly back.]

Without any wings, the fuselage just spins too fast and it doesn’t fly. So put a wing in-between the straws. If the wing is too loose, tape the straws together around here to make it a tighter fit.

Bending the wings up gradually is called dihedral and it adds flight stability. Splitting the wings is optional. You can also decorate.

This gauge can help you start with a propeller angle that gives you good flying. The concave or inside curve faces down. The gauge is parallel to the straws. The end of the blade that is facing you should line up with the gauge.

You can fly your Dragonfly now, but check out the flying tips to get best results.

FUSELAGE 2: FOAM GROCERY TRAYS

17.) I like recycled foam grocery trays and takeout containers best, but they are not available everywhere. [in some less-wealthy countries, they are never were available; in some wealthy, environmentally conscious places they have been banned] I do not like the ones with bumps because they are not as strong.

There are lots of ways to cut the foam. If you are making a lot, hotwire cutting is fun and fast. But scissors or razors work well, too. [this page is for hotwire cutting very thin foam for walkalong gliders, but still gives an ok introduction. ]

Some trays have thick foam and others thin. This one is strong enough even when the rubber band is pulling; but this one—yikes! Foam that’s 6 mm thick might be ok with a strip 2 cm wide [about 7/8”]. If it’s thinner foam, you might have to make the strip 3 cm wide to get enough rigidity. Or you can tape together 2 thin foam strips. The stiffness is a function of the square; even though it’s only 2 times thicker, it’s 4 times stronger. This thin foam from a takeout container was not strong enough even with 2 layers. But 3 layers worked. If it’s too flimsy, just add another layer.

Same as the straws, the fuselage is 14 cm long. Cut a square piece from the spacer strip and glue it on. Center the little tube on the square and spread a thin layer around for strength. Again, don’t let glue get where it will rub moving parts, or get it off if if does get on.

By the way, you can use the curved edge of the tray—precisely cut--as the spacer, instead of the glued on square.

The easy way to attach the rubber band in back is to cut two little slots, 1 cm apart. The knot always goes at the back, away from the propeller. A hacksaw blade also works well to cut the slots.

The wing goes on about 25 mm [1 inch] from the front end of the foam, with two pieces of tape.

Bending the wings up gradually is called dihedral and it adds flight stability. Splitting the wings is optional.

As with the straw fuselage, this gauge can help you start with a propeller angle that gives you good flying. You can trace the angle on.

Flying Tips

18.) As the propeller faces you wind up clockwise, a lot! The first 30 or so turns don’t do much, but when you keep winding so it’s twisted, knotted, double knotted, it really gets powerful. You can wind more than 150 turns.

19.) The reason these dragonflies are bouncing around is the propellers are not balanced. It’ll still fly ok; but to balance, take off the rubber band. The heavier side will always go down. Either cut a little off that heavier end; or, add some tape to the lighter end.

20.) When you want to see the highest it can go, rub some baby shampoo, soap bubble solution or even just soap lather or liquid soap into the rubber band. It makes it more slippery so you can wind it more and store more power. [do not put oil, grease, petroleum jelly or any other hydrocarbon product on the rubber band—it will destroy the rubber] Also put something soapy/slippery in the hub bearing to reduce friction.

21.) To make the helicopter fly upside-down with the propeller on the bottom, twist so the concave side also faces down. Assuming you wind it up the same way, the left side tilts up 20 to 25 degrees. [ The gauge gives you a good propeller angle and you can experiment to find an even better angle. But it won’t fly with too much or too little angle.]

22.) Avoid extremes of heat and cold. You can’t wind up as much in cold weather. Do not store rubber bands in sunlight.

23.) You can send time-release gliders up in your helicopter and make the auto-gyro returns, as detailed here.

24.) If you use a geared winder, not only can you wind faster; but you can put more twists in—and therefore more energy--because the rubber is stretched out at first. If you wind this way, you might want to make this kind of hook with a swab stick in the back.

[If you do use a geared winder, you can use rubber that’s up to 1½ times longer—so it droops. You start winding with the rubber quite stretched and get closer as it winds up. Experts use torque meters and other advanced techniques. They also use advanced lubricants (not baby shampoo that I use). I am not an expert, but even with my crude winding and lubrication the helicopters go almost out of sight, so I’m happy. If you know of good advanced resources on the internet and share it with me, I will share the links on this page. ]

25.) You can repair the wings with tape if they break. If the wings keep breaking, you can substitute with one made from a foam plate. They are heavier, but also more durable.

Off The Shelf Build

26.) So maybe you can’t, or you don’t want to buy the kit. That’s ok, but the most important part of the kit is the special rubber band made for flying models. I’ve experimented with everything—even making rubber bands from bicycle inner tubes. The fact is, Tan Super Sport rubber made specifically for flying models holds many times more energy than office or school rubber bands. Why go to the trouble of making a great machine, only to power it with low-quality rubber bands?

You’ll also have to use heavier steel paper clip for the propeller shaft, straightened out. Bend the hook in as per the previous instructions. Cut a 1 cm piece of cotton swab stick and slide it on. Instead of the tiny beads to reduce friction, you can make a washer from a scrap of the bottle. Make a hole with a tack and either punch it or cut it out. Put that on. Cut another swab stick to 5 cm and mark a hole in the middle. Punch the middle hole and put that on the paper clip, too.

We’ll use the same spacing trick as before when making this bend. Cut so there’s about 1 cm remaining—don’t use scissors for steel paper clips. Cut the slots in the end and tape, same as the variable-pitch design. But now we have to set good propeller angles. I used to glue on with a jig made from straws, but had problems with the hot glue warping the propeller. So now I use a 22.5 degree pattern. [Or you can make your own by folding 90 degrees to 45 to 22.5.] Tape to the lower jaw, at the flat part. Put one end in to the other side of the pliers. Then rotate left so the shaft is parallel to the pattern edge. When you squish the stick now, it will be at a good flying angle. From here on the propeller is the same.

Put something soapy here in the hub to reduce friction.

I’ve tried everything I can think of to get more power from regular office and school rubber bands. With regular rubber bands I get a burst of power, but it’s very short. I liberated the thin rubber strips from an old bungee cord. I was hopeful, but they only worked slightly better. [They are really difficult and time-consuming to remove. And they are difficult to line up and tie.] Just switching to Super Sport model rubber gets the dragonfly many times higher and it stays up many times longer.

I mentioned that making wings from foam plates or takeout trays is heavier than the wings in the kits (so they won’t go as high), but they’re also more durable. Grocery store trays are even thicker and heavier, but there’s you can experiment and maybe you’ll find a way to use them. I’ve also made wings by shaving weight off bamboo skewers, with paper. Reminds me of a bat [Grocery store trays are much thicker and stronger than they need to be for wings. So I’ve experimented with making thin slices that go out far away from the center of rotation; then putting wider winglets at the end. The winglets gain lots of mechanical advantage (leverage), for resisting the fuselage from spinning, by being away from the center of rotation. I started out with small trays because they are thinner (not as thin as foam plates, though). Then, for the outside winglets (white squares in the video). I sliced them to get two from one, half as thick.]

If this project worked well, please spread the word of a good science project. If it did not work well for you, please contact me, Slater, or leave a message in the comment section at the bottom of this page and tell me what’s happening so we can get it flying.