How EPS Foam Stacks up Against Paper for Gliders

It is difficult for people to understand that paper is very heavy when compared to foam. But imagine how heavy these stacks would be if they were books or newspapers instead of foam! The foam is cut into thin (0.6 mm) sheets, many times lighter than a sheet of paper of equal rigidity.

What is EPS foam?

EPS (expanded polystyrene) foam is the ubiquitous white foam made of spheres (beads) that appear as circles when cut, used to make everything from foam cups to foam coolers to molded electronics packaging to sheets of rigid insulation. It is made from hard, dense plastic polystyrene beads that are “puffed up” (expanded) like popcorn or puffed rice: mostly air. The expanded spheres are fused together.

Expanded Polystyrene foam is made in different densities (the ratio of weight to volume). In North America, density is usually still measured in pounds per cubic foot. In most of the rest of the world it is measured in kilograms per cubic meter.

There are lots of other kinds of foams—and I have experimented with many—but EPS always comes out on top, because it has the highest strength/weight ratio.

Why is EPS foam better than paper for walkalong gliders?

Not only is the sheet of printer paper 8 times heavier than sheet of foam with the equivalent surface; the paper is still not stiff enough to keep from bending too much. Everybody has wishful-thinking that paper will work well for walkalong gliders. It doesn't. And thin .6 millimeter foam is inexpensive to buy, or you can even slice your own.

Everybody wants to use paper because we are so familiar with paper airplanes and origami. But to match the rigidity of a .6mm slice of EPS foam requires a thickness of paper that is many times heavier. Weight is bad for gliders, at least when you are starting out. Heavy gliders fly fast. That’s ok if are good at walkalong flying and you want to race but bad for beginners, who need time to think and react as they learn to fly. There is an exception. The rotating kind of paper glider invented by John Collins (the Paper Airplane Guy)that he calls the “Tumbling Wing” and uses the Magnus Effect, flies more slowly. However, most people find the paper spinning gliders more difficult to launch and fly than foam gliders; and in humid weather, paper becomes limp and useless. But paper is free. You can see some paper designs here.

What is Time Warp Foam?

The lowest density EPS foam made in North America is custom made for me, specifically for gliders. It weighs 0.58 pounds per cubic foot (9.3 kilograms per cubic meter). For comparison, the lowest density EPS foam commonly available in North America (usually as insulation, sold in building supply stores) is 1 pound per cubic foot (16 kilograms per cubic meter). And it can be even denser.

I have to get the low-density foam a truckload at a time (shipped as a bunch of giant blocks measuring 3’ by 4’ by 8’) because there is no commercial use for it in North America. I do not mean to discourage do-it-yourselfers who want to cut their own foam. Even commonly available white insulation foam is much lighter than paper. And if you can find a furniture store where they import from China, you might be able to find lower density foam there (see below). It is used as packaging/padding for the furniture. You can see how to cut your own foam here .

Unless otherwise specified, the gliders and foam sheets sold by sciencetoymaker.org are Time Warp. UltraLight foam (see next entry) is even less dense, but it has to be imported.

What is UltraLight Foam?

There is also a special foam called UltraLight. In Asia (particularly China; I've heard maybe also in India) the manufacturers are allowed to use much higher concentrations of the bead-expanding agent, pentane. Pentane is regulated in most other industrialized countries. This EPS foam from China can have density as low as 4.5 kg/m3. If you consider that air itself has a density of about 1.225 kg/m3 (depending on altitude, temperature, etc.) then it’s is only about 4 times heavier than air, which is quite remarkable! By comparison, water is about 800 times more dense than air and paper is over 500 kg/m3 density.

So I call this extremely low-density foam that can only be made in other countries “UltraLight foam”. It is slightly less rigid than Time Warp foam and also a little more delicate to handle (rips more easily). But if you can handle it gently, the gliders made from it fly so slowly it's like magic!

Ultra Light foam is not actually one foam, but many similar foams from 4.5 to 7 kg/m3, manufactured throughout China. Each kind has it’s own personality and cuts differently. I do not usually make the foam that’s less than 5.5kg/m3 into gliders because that stuff has very large beads with very large gaps in between. The gaps do not affect the flight, but it does rip even a little more easily. Perhaps I will make it available to experimenters if there is interest.

So where do I find this royal class of extremely low-density UltraLight foams? In the recycling bin!! My good friend Rob Beiter manages several furniture/appliance stores in central Pennsylvania and has better things to do than collect foam scraps from packaging. And yet he kindly directs the rare bits of UltraLight foam from imported furniture packing my way because he supports recycling, science education and non-profit organizations like the Physics Factory.

Although Rob gives us the foam gratis, there is still a lot of processing. So recycled UltraLight takes lots of time for me to sort through, test density, custom cut, etc. (and there's not much of it), so it’s therefore more expensive. If you decide to cut your own foam, you might be able to find and recycle it locally—I recommend that highly

Under ideal circumstances (dead still air, people who can handle it very carefully) the ultra low-density UltraLight foam flies so slowly that it will take your breath away! That slow motion gives beginners lots of time to think and react, so I like to use it when teaching people how to fly. And again when learning to fly with hands-only deflecting the air up. You have to keep your hands at exactly the right place relative to the glider for hands-only flight, constantly recalibrating. That’s easier to do if the glider is moving slowly. Warp gliders are also superior when flying in small, cluttered rooms.

I see pinholes in my sheets of foam—is that a problem?

EPS (expanded polystyrene) foam is made of spheres (beads) that appear as circles when cut thin. The holes between the circles rattle some people, but do not affect flying. Foam gliders are superior, both for beginning and advanced flight.

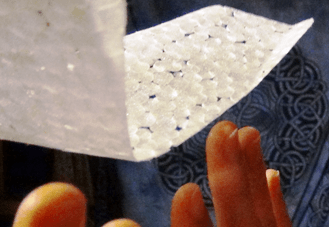

EPS (expanded polystyrene) foam is made of spheres (beads) that appear as circles when cut thin. Because EPS foam is made of expanded spheres, fused together, there are tiny voids between the beads. When we slice the foam very thin, the voids appear as tiny holes. I have experimented with solid foams like Depron that do not have voids, but invariably they are less satisfactory because they weigh much more.

The pressure differential between the top of the gliders and the bottom is very small. The relative viscosity of the air going through tiny holes is high. So the pinholes might be an esthetic problem, but not a flight problem. The lowest-density Asian foam (4.5 KG per Kilogram) has bigger beads, and therefore bigger voids (again, they do not negatively affect flight but do rip easier).

Can you slice your own foam?

Yes, you can collect and slice your own foam. This page and associated video show how. Flying even with heavy foam is many times better than flying with the lightest paper gliders. And if you can find packaging foam from China (see Ultra Light foam section) you will love it. Cutting foam is quite easy when you have Nickel-Chromium (ni-chrome) wire, which is special for two reasons. It is high resistance, so it creates heat instead of a short circuit; and then it stays strong even when hot (unlike regular steel wire). Almost all electric heating devices--from hot plates to water heaters, soldering irons to coffee makers--use ni-chrome wire. It's the stuff that glows orange in toasters, although we don't use it that hot to cut foam.

Hot wire cutting produces some smoke. You are responsible for cutting in a well ventilated place, such as a garage with the big door open; or under a stove exhaust hood.

Paper vs. EPS foam: The numbers

Flying even with heavy foam is many times better than flying with the lightest paper gliders. And if you can find packaging foam from China (see Ultra Time Warp foam section) you will love it. Cutting foam is quite easy when you have Nickel-Chromium (ni-chrome) wire, which is special for two reasons. It is high resistance, so it creates heat instead of a short circuit; and then it stays strong even when hot (unlike regular steel wire). Almost all electric heating devices--from hot plates to water heaters, soldering irons to coffee makers--use ni-chrome wire. It's the stuff that glows orange in toasters, although we don't use it that hot to cut foam.

Hot wire cutting produces some smoke. You are responsible for cutting in a well ventilated place, such as a garage with the big door open; or under a stove exhaust hood.

The density of EPS foam is as low as 6 kg/cubic meter (Ultra TW foam). Time Warp foam is 11 kg/m3 (and stronger). Paper is 540 kg/m3. That's not really fair because paper is thinner than foam sheets used for gliding.

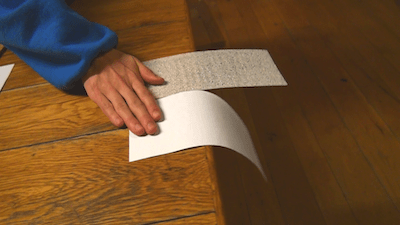

So lets set up a fair comparison. 10 sheets of EPS foam, cut to the standard size that I use for both Baby Bugs and big Mama Bugs (219 mm by 96 mm) weigh 1.3 grams (Ultra Time Warp) or 2 grams (Time Warp). 10 sheets of printer paper cut to exactly the same size weigh 16.6 grams. That's more than 8 time heavier than even the heavier foam.! Furthermore, the foam is much stronger. Holding the end of a piece of foam so that it sticks out horizontally like a diving board, foam bends just a little bit. But paper cannot hold itself rigid at all. You can say that all you have to do is fold/bend the paper so as to increase its rigidity, and many people have done just that: developing clever designs to maximize the strength of paper with folds. But in the end, paper walkalong gliders are far heavier, much more difficult to trim (adjust) and they fly so fast that it takes hours for newbies to be able to fly. And that doesn't take into account the fact that paper becomes even more limp and useless in all but the lowest humidity air.

10 sheets of thin-cut EPS foam weigh only a couple of grams, and the foam is still more rigid than the paper

I started with paper gliders because I did not know about thin foam gliders. It was frustrating to try to teach my students how to fly walkalong gliders. It took a long time and many students never got it. It only worked in winter when the air was very dry. When I started using foam, I could get everybody flying. Some kids still worked harder and excelled more than other students, but everybody got into the air. I have not worked with paper gliders for years, and I don't miss it.

Measuring foam density

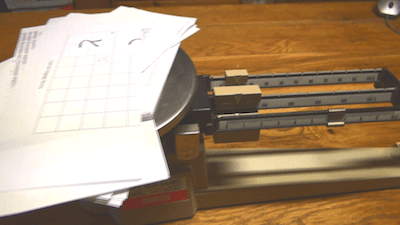

Density is weight divided by the volume (length x width x height) of the foam block. In North America it is expressed as pounds and feet, but I (and the rest of the world) prefer metric kilograms per cubic meter. You can easily convert to pounds/foot if you need to.

I use a triple beam balance to measure weight but you could use a postage scale. I express 6 grams as .006 of a kilogram in my equations; 22 cm as .22 of a meter; 95 mm as .095 or a meter, etc.