You can find more details here about steps covered in the Hotwire Cut Foam for Walkalong Gliders video. Use the numbers in the upper left corner of the video to find the corresponding number here. If you still have questions, feel free to contact me .

Note: The names of the foam types have been changed.

- Time Warp North America foam is now called Time Warp Foam.

- Time Warp Asia foam is now called Ultra Light Foam.

We no longer sell the hotwire foam-cutting kit because now there are several good ways to cut precisely without the special bronze machined part. Learn more about here.

If YouTube is blocked at your school, video try this MPEG file (33 MB) file. Depending on your browser it might stream when you click, or you might have to right-click and "save as".

This is an add-on video to the video above. It shows how to make a hotwire foam slicer with common materials:

Index

- Introduction

- Paper vs. Thin EPS foam

- How the Kit Works (but you don't need the kit. )

- Make the Hotwire Foam Slicer with Common Materials (this is in the add-on video)

- Make the Rough-Cut Part

Introduction

1.) On this page you can find details about slicing your own sheets of foam for walkalong gliders—more text than can be put in the video. The numbers correspond to numbers in the top-left corner of the video.

2.) Walkalong gliders are so efficient that you can surf them on a wave of air, similar to the way that large birds can soar on updrafts of wind. But the gliders have to be efficient; you can’t just make them out of anything. Before showing you how to hot-wire cut foam, I will show why foam works better than paper, particularly for starting out.

3.) If cutting your own foam is too much, you can get thin sheets of foam cut on a robotic CNC hotwire cutter inexpensively from the Gliders and Foam Store.

4.) Or you can hot-wire cut your own foam sheets from scratch with an electrically heated ni-chrome wire, using recycled packaging foam and a common car battery charger.

Paper vs. Thin EPS Foam

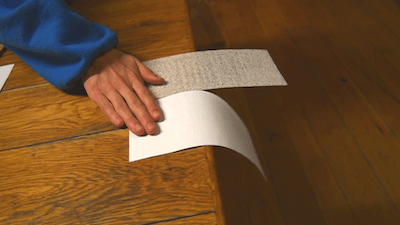

5.) Everybody wants to use familiar paper at first. But thin sheets of common expanded polystyrene or (EPS) foam are many times lighter and stronger than paper. EPS is the white foam made from spheres or beads, that’s widely used for insulation and disposable packaging.

EPS foam can be as low as 6 kilograms per cubic meter. When you consider that air itself is about 2.2 kilograms per cubic meter, then you can see that EPS foam is only about 5 times denser than air! It almost floats and it is able to stay rigid.

6.) Let’s compare paper to EPS foam. 10 sheets of printer paper--cut to the standard size I use for gliders--are over 16 grams. 10 sheets of EPS foam only weigh 2 grams. Printer paper is 8 times heavier and still not stiff enough to keep from bending too much. It would take a thicker piece of paper to have the same rigidity as the sheets of foam even under ideal circumstances (dry air). When the air is humid, paper becomes even more limp.

The measure of 2 grams for 10 foam sheets is an average: 5 sheets each of the 2 kinds of foam that I work with. 10 sheets of Time Warp Asian (Ultra Time Warp) foam weighs a little less, 1.3 grams. North American (I call it Time Warp) foam weighs a little more, 2.5 gm. The point is, even the heaviest foam is many times lighter and stronger than paper.

7.) You can also see the difference between EPS and paper when you drop a piece of paper and a piece of foam.

The extra weight of paper creates a vicious spiral. Because the paper walkalong gliders are heavy, they fly faster.

The wind rushing other the wings creates fluttering in the paper, requiring even stiffer paper and more weight. The extra weight also requires a front weight that is much heavier, to balance the body. I also find heavier gliders to be difficult to adjust (trim).

Big Mouth Tumblewing

Paper Airplane Walkalong Gliders by Phil Rossoni

John on Conan. His paper designs—including the classic Tumblewing that he invented--are in his books.

How Kit Works

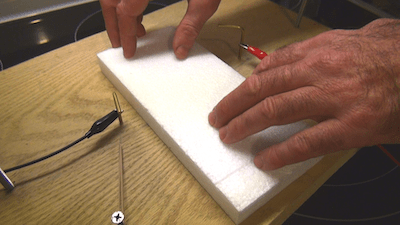

8.) The sciencetoymaker kit allows you to heat ni-chrome wire—the same kind of wire that you see in a toaster--first to rough-cut blocks of recycled foam, and then slice very precise sheets.

The kit supplies several difficult to find items, including ni-chrome wires, bronze threaded and machined parts that allow very precise cutting; while you supply the bulky but easy-to-find locally things: a flat board; threaded rod from the hardware store; a 12 volt car battery charger. The sparks look scary, but you can not get a shock from 12 volts unless you stick your tongue on the wires.

9.) Parts List (that you supply):

- Smooth, flat board, preferably at least as big as 30 cm x 40 cm (12” x 16”). It should be at least 12mm (½”) thick. Thicker is better). You might be able to use something that you have around, like an old shelf or something

- Threaded rod—at least 6 mm (¼”) diameter. In North America, threaded rod usually comes in 36” lengths at hardware stores and costs a couple of dollars. Perhaps 1 meter lengths of M6x1 are available in other countries.

- 12 volt car battery charger (or hook directly to a car battery). Although these will make impressive sparks if you click the leads together, you can NOT get a shock from 12 volts unless you lick them—even if your hands are wet. 2 amp or higher car battery chargers are definitely powerful enough. I tried the cheapest 1 amp charger that I could find and it worked. If you don’t want to buy one, you probably know someone who can loan you one. Or you can get them at auto parts stores or department stores.

Tools You Will Need:

- Drill, drill bits, hack saw, pliers, screwdriver.

10.) You rough-cut blocks of foam with the thick ni-chrome wire. Then you fine-cut the foam into precise sheets with threaded, notched bronze “L” pieces and fine ni-chrome wire. You fine-tune the thickness by turning the Ls in or out.

Make the Hotwire foam Slicer with Common Materials

Full Transcript of the Add-On Video

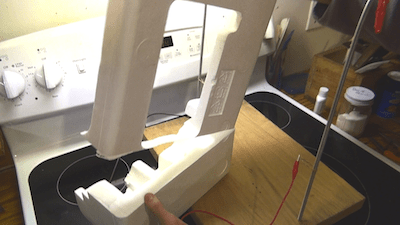

Hi it’s Slater. This video is an add-on to a detailed video about hotwire cutting foam paper. That is, making thin sheets from blocks of expanded polystyrene foam for walkalong gliders; or thicker ones for dragonfly helicopter wings. Getting the right foam thickness for the gliders requires very precise positioning of the hotwire. In the past video I featured a special bronze part for doing that. A machined groove lifts and lowers the hotwire. It works well, but wouldn’t it be good if you could use an ordinary, cheap, bolt that’s available locally? This video shows two ways to do that.

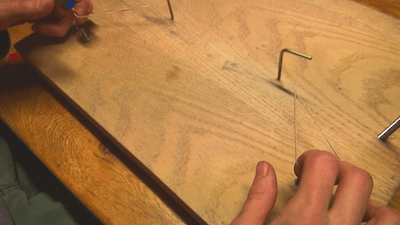

You cannot just have a bolt that’s threaded in, like this. When the bolt is turning and going down, the wire against the thread is moving up—so it doesn’t actually move at all. One strategy that does work is to drill out the holes a little bit too big for the bolt—it slips through. But the hole has to have a bottom—here I’ve flipped the board over and I’m gluing coins on the bottom. I also made some hot glue feet so it’s stable.

The bolts slide in. When rigged with the wire, the turning bolt does not move up or down; but the wire against the thread does. You can hook the car battery charger directly to the bolts. Here I’m cutting a thick piece for a dragonfly helicopter wing.

These are actually ¼” or M6 threaded rods. A finer thread like this would give more precise adjustments.

A different strategy—even a bit more precise--is to add a screw that’s flat on the bottom here and usually has a round-head on top. The wire is always a little higher up on this outside screw. When you turn this inside screw right next to it, it places the wire very precisely to the right height—both down and up.

As with all hotwire cutters, the resistance wire is kept under some pull tension, in this case rubber bands. I hook the car battery charger to the outside screws—drywall screws.

The sharp ends of the round-head screw are sticking out the bottom, so again I’m making little hot glue feet to raise the bottom up

Thanks to Sekino san in Japan for coming up with this design.

Here is Mr. Hirohisa Sekino's hotwire foam slicer page.

Thin nickel-chromium resistance wire is very cheap and you could even scavenge it from a broken soldering iron.

You should be able to adjust the tension. I think it’s easier to make adjustable rubber loops than it is to move these anchor screws. I cut and tie into an overhand knot. If you try to move the knot, it will probably break. But if you rub in some slippery soap, you can pull next to the knot and move it.

We attach the wire by kind of hooking around, then twist. If you don’t twist enough, it will pull off. Spreading the wires as you twist helps prevent that.

I hook on at one end. Then I stretch the rubber at that end as I hook the other end on or else it could break getting it on.

This is just an update. It does not replace the other video that talks about foam vs paper, how foam is not all the same, calculating density, how to rough-cut foam blocks first, how to control heat, where to get foam, etc.

I know this will sound self-serving, but even if you plan to cut your own foam—and I encourage that--it’s still a good idea to buy a few gliders. Most people bumble around and waste time trying to figure out the right thickness and rigidity for gliders.

(End of the Add-on Video Transcript)

Make the Rough-cut Part

11.) Cut the piece of threaded rod in half.

Drill two holes in the board about 38 cm (15”) apart in the middle of the board as shown, using a 6 mm (1/4”) drill bit. If you are not using am M6x1 or 1/4" threaded rod, then you will have to figure out what size hole to make for the rod to thread into.

Note: The rod is sturdier if it threads into the board. A ¼” or 6 mm drill might seem too big since it’s the same diameter as the rod. However, I’ve found that wood fibers have a little “give” and the rod still threads in (easily).

Slant the drill a bit away from the board. Otherwise, the rods tend to lean in when the ni-chrome wire and rubber bands pull them inward.

Having the rods stick out is dangerous. At the least you should put something on top to protect against getting accidently speared or poked in the eye. I just bent the threaded rod over, but don’t bend so tightly that they break.

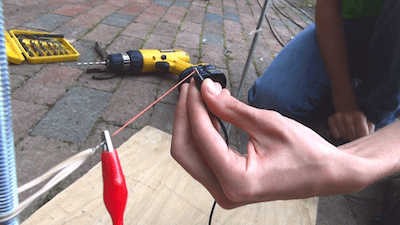

Thread the rods in until they are sturdy.

12.) Cut a piece of the 30 gauge (thicker) ni-chrome wire [about 30 cm (12”) long]. Note that with wire, the lower the wire gauge number, the thicker the wire is. This is counterintuitive, having to with how many steps it took to draw the wire through holes to make it thinner and thinner. So 30 gauge is the thick wire; 38 gauge is the thinner wire. Twist the ends of the wire onto rubber bands so that the rubber bands are always stretched when strung on the rods. In the video my rubber bands were too long so I folded in half.

Ni-chrome wire always has to be under some tension because it expands a little (gets longer) when it heats up. You might have to fiddle a little with where to connect the rubber bands before you get it right. You can tie knots in or double-up the rubber bands if they are too long.

Rough-Cut Foam

13.) Hot-wire cutting releases irritating smoke. You could do your cutting on top of your stove if the fan discharges outside (some just recycle the air back). Or you could cut in a garage with the big door open. The smoke rises, so keep your head to the side so you don’t stick your nose in it.

I have not found reliable information that smoke from hot-wire cutting is particularly toxic or carcinogenic in the way, say, hexane or asbestos are. But it’s never smart to breath smoke.

You can reduce the amount of smoke/fumes generated by lowering the temperature of the cutting wire. The longer the distance of the ni-chrome wire between the alligator clips, the cooler the wire will be. It will then take longer to make each cut. Experiment.

Always remember that the foam has to be completely dry. Just a drop of water will stop the cutting cold.

The clamps of the car battery charger are too big, so attach the smaller alligator clips that come with the kit. Then simply clip onto the far ends of the ni-chrome wire— not too close to each other. If you need to, you can control how hot the wire gets by moving the alligator clips closer to each other. But when the wire glows orange, it’s much too hot and can break.

Measure where you want to make the cut and make sure the foam is flat on the board as you cut. It’s that simple. I cut my blocks to about 10 cm by 22 cm (3 ¾” x 8 5/8”) for both small Mosquito gliders and double big Mama Bug gliders, but you can cut whatever size you want.

Make the Fine-Cut Part

14.) Cutting the actual foam sheets for gliders requires more precision and a finer wire.

The finer 38 gauge wire breaks easier.

I suppose you could just use the thicker 30 gauge wire for your foam sheets and avoid the hassle, but it melts a bigger kerf. That melted plastic has to go somewhere. It gets deposited on the foam sheets, making them heavier. But if you hate the fine ni-chrome wire because it breaks easily and it’s hard to see, then try the thick wire even for fine cutting.

Drill two holes for the bronze “Ls” to thread into, 15cm (6”) apart, between the threaded rods as shown. Use a 3 mm (1/8”) drill. If any wood fibers stick up, scratch them off with a fingernail until it is flat around the hole so.

Unlike the rough-cutting wire where you could adjust the heat by sliding the alligator clips, you don’t adjust the heat for fine-cutting. If you are using very heavy, dense foam that cuts very slowly, you could make the bronze “Ls” closer to each other to increase heat. Or, if you want to make the wire cooler to minimize smoke when you cut—or cut a very wide piece of foam—then you can add a hole that’s farther away from the first.

Screw in the Ls until the groove is close to the board.

15.) Cut a piece of the thinner 38 gauge ni-chrome wire about 23 cm (9”) long. Twist the ends onto rubber bands at least 5 turns so it does not come off.

The ni-chrome wire will bend around the bronze Ls at about a 45 degree angle, and rubber bands will hook onto woodscrews. Hold the wire this way with the rubber bands stretched a medium about and try to guess where the screws should go. If it’s not the right amount of tension you can put the wood screws in a different position. Half of the maximum stretch of the rubber bands is good. If your wire keeps breaking, try less tension.

The ni-chrome wire will bend around the bronze Ls at about a 45 degree angle, and rubber bands will hook onto woodscrews. Hold the wire this way with the rubber bands stretched a medium about and try to guess where the screws should go. If it’s not the right amount of tension you can put the wood screws in a different position. Half of the maximum stretch of the rubber bands is good. If your wire keeps breaking, try less tension.

16.) Push the wire into the L grooves. Notice that when you rotate the L, it lowers or raises the wire very precisely.

Calibrate the wire level so it cuts slices that are the same thickness on both sides. Do this by screwing in the bronze L in until the ni-chrome wire just barely touches the board (that’s why you used your fingernail to scratch off the wood fibers when you drilled the hole); on both sides. Then screw the Ls out (counter-clockwise, so the wire is no longer resting on the board) exactly one turn. In the future, when you adjust the cut thicker (counter-clockwise) or thinner (clockwise), turn both sides the same amount.

Calibrate the wire level so it cuts slices that are the same thickness on both sides. Do this by screwing in the bronze L in until the ni-chrome wire just barely touches the board (that’s why you used your fingernail to scratch off the wood fibers when you drilled the hole); on both sides. Then screw the Ls out (counter-clockwise, so the wire is no longer resting on the board) exactly one turn. In the future, when you adjust the cut thicker (counter-clockwise) or thinner (clockwise), turn both sides the same amount.

Fine-Cut Sheets

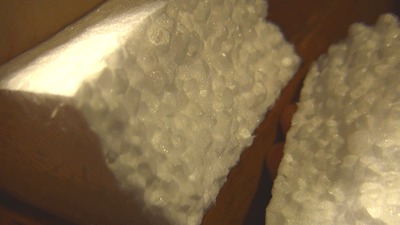

17.) I’m going to start out with the worst EPS—molded packaging foam. It’s usually hard so it cuts slowly; and it’s heavy, as foams go. It looks like you could get some good flat sheets from it, but there are so many voids that you won’t get much. Yet, as bad as this stuff is, it’s easy-to-find and it’s still many times better than the best paper.

I hook up the alligator clips to the Ls and try cutting a slice. The first one or two cuts are never good so don’t get discouraged. Push the foam forward gently so as not to deflect the wire a whole lot. This heavy foam is a little wavy, but it will work.

18.) Here I’m going to try a lighter (lower-density) foam. Notice how it cuts faster. But it’s cutting a little too thin now, so let’s turn out both bronze Ls one quarter turn out. With lightweight foams I raise the wire a little. Perfect!

You decide what thickness to make foam. Too thick is too heavy. Too thin isn’t strong enough. A good slice has some flex, but not too much. The screw threads in the “L”s advance 1/32” (about .8mm) in each turn. That means that each time you twist the Ls 45 degrees, you lift or lower the wire by 1/10th of a millimeter.

However, if you have raised the wire .8 mm above the board, that does not mean that you will make sheets that thick .8mm thick. Some foam will be melted away (the “kerf”). How much is melted away depends on how dense the foam is; how hot the wire is; and how fast the foam travels. I find that the ni-chrome wire makes a wider kerf in lighter foams. So that means I have to turn out the Ls a little more—making the wire higher—to get the same thickness of light foam compared to heavier foam. All of this will become intuitive as you cut foam.

Measure Thickness

19.) You might not need to know a numeric measure, depending instead on getting a feel for how stiff it should be.

You can’t measure the thickness of a sheet of with a ruler. A dial gage is expensive, about $100 U.S. If you do get one, make sure that the part that touches the foam is wide, or it will crush the foam. That would give you an inaccurate measurement.

You can’t measure the thickness of a sheet of with a ruler. A dial gage is expensive, about $100 U.S. If you do get one, make sure that the part that touches the foam is wide, or it will crush the foam. That would give you an inaccurate measurement.

A workaround for an expensive piece of equipment is to cut 10 squares and stack them together. If 10 sheets measure 6 millimeters, then 1 sheet is 1/10th of that: .6 or 6/10 of a millimeter.

.6 mm (6/10 mm) is a good thickness to start with. If it’s too rigid and heavy, go thinner. If it’s to flimsy, go thicker.

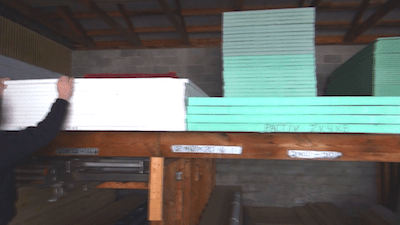

Finding Foam

Lets step back a moment and disambiguate the common polystyrene foams. The foams made from the spherical beads are EPS - expandable polystyrene. Sometimes it is called "bead board". It is used in a lot of cushion packaging (for appliances, computers, etc.), in many hot drink cups and in thermal insulation, usually all white. It is closed cell foam. Egg cartons, meat trays, clam shell food service, some cups (with a seam down the side), and some insulation (e.g. blue and pink board at Lowes or Home Depot) are XPS - extruded polystyrene foam. It is also closed cell foam. I think that "Depron"--a common material for making model airplanes--is also extruded polystyrene.

Lets step back a moment and disambiguate the common polystyrene foams. The foams made from the spherical beads are EPS - expandable polystyrene. Sometimes it is called "bead board". It is used in a lot of cushion packaging (for appliances, computers, etc.), in many hot drink cups and in thermal insulation, usually all white. It is closed cell foam. Egg cartons, meat trays, clam shell food service, some cups (with a seam down the side), and some insulation (e.g. blue and pink board at Lowes or Home Depot) are XPS - extruded polystyrene foam. It is also closed cell foam. I think that "Depron"--a common material for making model airplanes--is also extruded polystyrene.

The egg cartons, meat trays, and clam shells are first extruded into large foam sheets. Subsequently, these sheets are thermoformed into the final end-use articles. The extruded foam cups are typically two

pieces - with the side (with a seam) and the bottom being separate pieces.

I've given the strict definitions. People are sloppy on web sites and in their advertising and incorrectly use EPS, XPS, and Styrofoam names. Some people even call polystyrene "styrene" which is completely wrong. That doesn't even get into the spongy, open cell foams like polyurethane, which is used for seat cushions; and sprayed foams. There is also some kind of paper-like foam used to wrap delicate parts for shipping. Everyone thinks it will make great walkalong gliders, but is not rigid enough.

20.) Expanded polystyrene foam (EPS) foam all seemed about the same to me at first, but with experience I become aware of the diversity: heavier stuff, lighter, big beads and smaller beads. Any EPS foam will work far better than paper, but some foams are clearly better for gliders than others.

I’ve already mentioned why I don’t use molded packaging foam (heavy, slow-cutting, full of voids) anymore, but it will work in a pinch.

21.) For a long time I used discarded shipping boxes from the seafood department of grocery stores. However, these boxes are made to be strong and impermeable, so the foam is heavy and slow-cutting. Still, it was the first recycled foam that I could that would give me nice flat sheets without a lot of waste. If you don’t mind gliders that fly a bit fast, seafood packages work well. If you stick your nose up to the gliders, you get a slight whiff of the ocean!

22.) Eventually I discovered the discarded packaging foam from a furniture and appliance store. There were big pieces and then I stumbled on some foam from China that was much lighter than anything I’d seen before! At 6 to 7 kilograms per cubic meter density, it’s only 4 times more dense than air. I call it Time Warp Asia foam. When you are that close to floating, the aeronautics become different—in a good way. Glider flight is astonishingly slow and easier to adjust.

There is some foam from China that is even lower-density: between 4 and 5 kg/M3. However it has large beads (spheres) and—correspondingly—large gaps in between. The gaps do not seem to hurt the gliders. Indeed, they fly very well, but having big holes in the gliders puts some people off.

There is some foam from China that is even lower-density: between 4 and 5 kg/M3. However it has large beads (spheres) and—correspondingly—large gaps in between. The gaps do not seem to hurt the gliders. Indeed, they fly very well, but having big holes in the gliders puts some people off.

By comparison, the lowest density foam that is manufactured in North America is heavier: 11kg/M3. However is a bit less prone to ripping.

Time Warp Asia (I now call Ultra Time Warp) foam is very small part of the waste stream, but if you can make connections with a conscientious furniture/appliance place, you might find it. I get from Beiters, which has several stores in central Pennsylvania. Rob Beiter is a very conscientious person who goes out of his way to support community projects and he diverts the ultra-lightweight foam to us. I don’t know if you will be lucky enough to find someone like that but it’s worth a try. Perhaps taking some gliders in and showing what you’re doing would help.

23.) In my experience, only the bead foams work well for beginners. People do make gliders out of disposable foam plates, egg cartons, meat and produce trays (also extruded polystyrene XPS) but—as is also true of extruded blue and pink building insulation--that foam is heavy even when sliced thin. The resulting flight is fast, which is difficult for beginners to learn with. However, the heavier gliders are more durable and are better at flying outside, when there is a slight breeze. If you don’t mind trotting to keep up with it, try it. Tyler MacCready’s design used Depron-like foam.

Phil Rossoni shows how to use already thin foam to make a walkalong.

Measure Density

24.) Knowing the density of foam is the most important thing, in my opinion. I can pick up foam, feel the weight, feel the softness or hardness (lower density foams are softer—not spongy, but noticeably softer). From handling it I can make a guess of the density. But even after years of working with foam, some of my guesses are off sometimes, so I never fail to measure density the proper way and figure out the number.

To calculate density, you weigh the foam block and measure the width, length and height; dividing the former by the latter. W x L x H / Wt

In North America, foam is measured in pounds per cubic foot, but it’s easier to just figure it out with metric measurements and convert it if you have to. It’s usually expressed in kilograms per cubic meter (kg/M3). So when you are calculating, enter 6 grams as .006 of a kilogram. 22 cm is .22 of a meter; 95 mm is .095 of a meter, etc.

To give you an idea of ranges, in North America ¾ lb/ft (=12 kg/M3) density is light (one or two N.A. companies make it as low as .7 lb. density); 1 ½ lb/ft3 (=24 kg/M3) density is heavy; one pound density foam (16kg/M3) is average. But if you are fortunate to find foam from China (Time Warp Asia) you can find density of 6 or 7 kg/M3. Light foam cuts faster and easier as well as flying more efficiently and slowly. I send a sample of Time Warp Asia with the foam cutting kits so people know what it is.

Once you have thin sheets of foam, anybody can cut and fold them into walkalong gliders. So you can practice a kind of aeronautical alchemy; transforming scraps of packaging foam into gossamer flyers that soar like birds.

Once you have thin sheets of foam, anybody can cut and fold them into walkalong gliders. So you can practice a kind of aeronautical alchemy; transforming scraps of packaging foam into gossamer flyers that soar like birds.

There are many more videos and text pages in this series about walkalong gliders: How to fly them; how to make the small and big gliders; how to mass-produce gliders; how to repair gliders; and how to go about designing your own gliders.

Odds and Ends

Here is an earlier web page and video about hot-wire cutting foam for walkalongs, via WayBack Machine. Some of it's out of date, but you might glean something from it.

Here is an even earlier web page and video about hot-wire cutting when I was still using batteries, from 2011! (again, via WayBack Machine)

And this was my first foam glider from 2010!

All links about how to make walkalong gliders when you have the thin foam sheets, where to get thin sheets if you don't want to make them, how to fly the gliders, what you need to know to create new walkalong glider designs, etc. are here.(Instructions and patterns are linked there.)

Jim Annweton's Design: I got some really interesting DIY cutter feedback from Jim Annerton of Huntsville, Alabama. Years ago I started adjusting the distance between the board and the hotwire with shims--and I hated them. They would slip and compress and generally cause problems, so I was happy to leave them when I discovered that I could use screw threads instead of shims. But Jim's design avoides the problems I had with shims by piling up very thin brass washers (some as thin a 0.005") which are skewered on upright clevis pins. So unlike my shims that would slip and slide, Jim's stay put. Then, a compression spring is also skewered on the clevis pin and is held under compression with a cotter pin at the top. So the wire always stays at the right level.

Jim's design might not be for everyone. Jim had the stuff around his shop, but if you have to buy the special brass washers (though knifemakers suppliers), then you could be getting into some money. But it's a brilliant design and it solved the issues I had with shims. Jim reports that when he flew his gliders, "My two granddaughters (aged 7 and 4) loved to watch and try them. The first words out of their mouth when they saw them was, "How are you doing that?" :)" And Jim is already scrounging for foam at his local furniture store and experimenting with Asian foam.

I'd like to know how this project goes for you. I'm happy to answer questions about it. Feedback from you is an important way for me to know what works and what needs clarification.