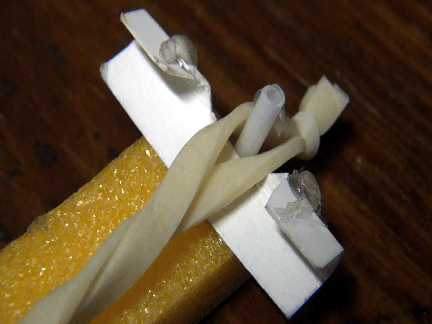

You can just wedge the gliders between the rubber band and body. Of all the modifications that I've tried so far to make releasing more consistent, this one seems to help a little with not much effort. It's just a bit of thin cardboard folded into sort of a channel. It keeps the gliders from tipping out too quickly.

This page is about sending gliders up with Dragonfly Helicopters. As the rubber band unwinds, it pushes out the gliders.

This challenge of releasing gliders high in the air can be as simple or complex as you want, and there’s a lot of development that needs to be done. You do not have to be an engineer or even an adult. What we do need is people who will experiment and share with the larger community. I will be happy to share your insights with the world on this page (and credit you) or link to your web-page or video, or whatever.

Here are some thoughts to get you started.

Notice that the rubber band unwinds much faster (in revolutions per minute) near the propeller, and much slower at the tail end. Theoretically, you could time the gliders depending on how far to the top or to the bottom you wedge in the gliders under the rubber band. But in my experience, the gliders launch before the helicopter has reached full height (if they drop out at all), so I always put them right at the tail.

Although in the videos I place the rubber band right at the center of the gliders, you should be able to time the release more precisely by where the rubber band is on the gliders. This is promising, but the gliders often tip. I have experimented with a thin cardboard track or wall to keep the gliders perpendicular to the body (fuselage) of the copter longer, until they are about to drop out. And it seems to help a little.

Even with the best engineering, it’s going to be a huge challenge to get consistent results. Here are some variables that I will affect when the gliders release (and if they release): how much you wind up, how stiff the gliders are (as per humidity or what kind of paper or how beat-up the paper is); how much friction there is against the rubber band vs. the Dragonfly body; how many gliders there are (affects thickness); how the gliders have been folded, how much of a gap between the rubber and body, how far in and how straight the gliders are placed…and so on.

There are so many possible ways to improve the timing mechanism! It requires people like you to experiment with ideas. Contact me, Slater, if you have questions or if you figure out how to make the timing better.