Full Transcript

Hi, it’s Slater.

This video is about using your hands to make, and then power, a helicopter that flies far beyond the reach of the highest trees. It’s a sort of aeronautical alchemy, transmuting stuff you have around the house into a really good flying machine. Everybody gets in the air and there’s no limit to how far you can take it. You could even morph it into an airplane, although airplanes are much more challenging to get stable flight. So master the helicopter first.

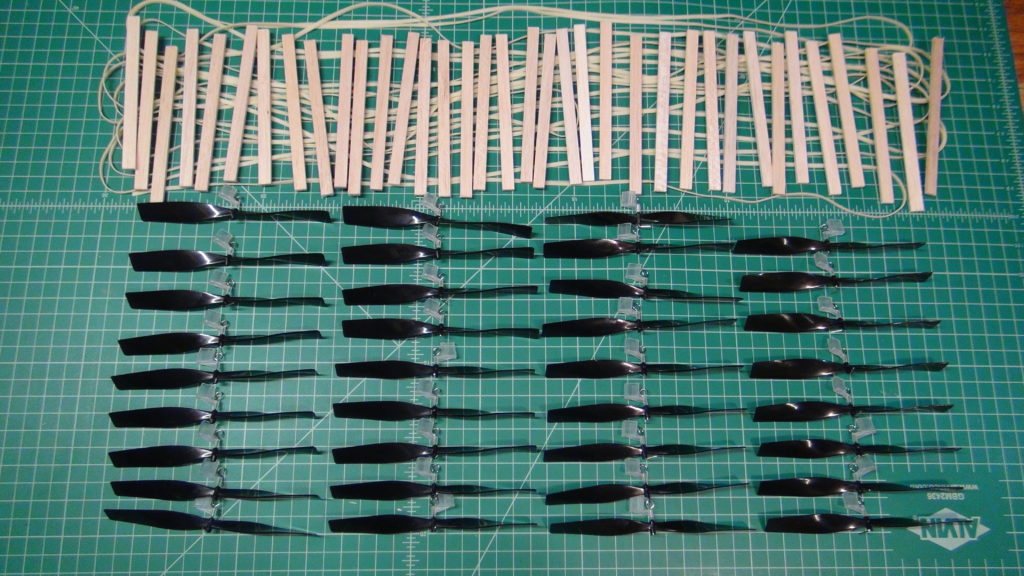

I already have two videos about making dragonfly helicopters: one design has an adjustable propeller—you can even switch it to make the helicopters fly upside-down—with the propeller pushing from the bottom. The other design uses and already-made propeller and balsa stick, so even young kids can assemble it. I’ve made that design with crowds of people and second grade classes

My friend Rick Schertle, who quite literally “wrote the book” about DIY flight projects suggested a collaboration for a dragonfly design that uses common stuff that people have around the house. Rick is writing the article for MAKE magazine and I’m making the video with a lot of visual detail.

For the fuselage we’ll use 2 plastic straws; or—if you can find it--a foam grocery tray. And we’ll need a wing to keep the fuselage from spinning. That can be paper or foam from a plate. We’ll use a small paper clip, 2 plastic swab sticks and a two-liter bottle for the propeller.

But, aye, there’s the rub—the rubber band. I get it. Common office rubber bands are around here and now. If you’re ok with a helicopter that just hits the ceiling, then school and office rubber bands will do that.

But know that model airplane rubber will fly more than an order of magnitude higher. That’s because you can wind it way more. And it’s cheap. If you don’t want to buy a lot of it, you can get a small amount in an envelope.

We’ll use these tools razor, push pin, clear tape, long nose/needle nose pliers and scissors. We want the cheap, 10 watt low-temperature hot glue gun, not the big industrial kind.

Print out the pattern 100% scale. Do not “fit to page”. You can check the size here.

We’ll start with the bearing part of the propeller assembly.

Straighten out a small paper clip for the propeller shaft. The first time bending the rubber band hook won’t go this fast. But these steps on the pattern page might make it easier. Use the very tip of the needle nose pliers at the very tip of the wire. Push your finger right against the wire to make a sharp, 90 degree bend. At each step you can compare it with drawing. After 3 bends, we need a 45 degree bend to center the square like a diamond. Don’t lose it.

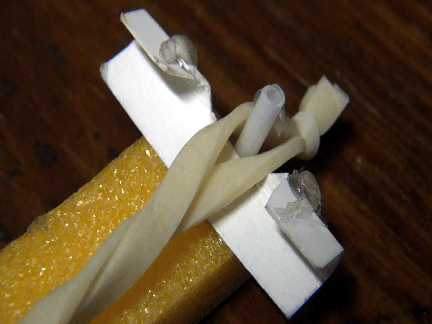

Make the propeller shaft bearing by marking off a 13 mm section and cutting it, not slanted. It’s hollow, so slide it onto the propeller shaft. Save this part.

Cut a small piece out of the 2-liter bottle. Make a low-friction thrust bearing by punching a hole and cutting out a tiny washer. Using a paper punch makes one that looks better. Slide it onto the wire.

Take the cotton off that other swab stick. (Hot water makes it easier). It does not have to be exactly as long as the pattern, but do center it so you mark in the middle. Punch a hole in the middle and slide it onto the wire.

Notice the tip of the pliers are gripping on top of everything. Make the bend above the pliers-- a sharp bend. There’s a cutting part of most long-nose pliers. Cut so about 1 cm remains. (no, don’t use scissors)Use about 1 cm of tape to hold the wire on tightly.

Hey, it’s taking shape! We’ll finish the assembly by establishing a good propeller angle and cutting out the blades.

Cut out the angle gauge—(the two straight lines are the important ones). The long nose pliers have a flat part here. Tape the bottom of the pattern to the edge of the bottom of the pliers—lined up exactly. The corner angle is within the flat part—not to the cutting part. A propeller strut end goes into the flat part, but not past it. We have to get the shaft and bearing to line up parallel with the edge of the angle patter, like this. Squeeze the pliers to flatten the swab stick. (Turn around and do the other end.)

I wish that I knew a better way to keep propeller blades on securely than cutting the folds we just made—and cutting toward my fingers with a really sharp razor blade. I cover and protect my fingers. I could also use a glove. (creates 2 flaps) If you are a kid, ask an adult to help you with this.

If you’re just making one helicopter, use this pattern. Tape it on and cut out two propeller blades. If you’re making a lot, use this pattern.

What was the outside of the bottle is convex and the inside curve is concave. The concave inside of the bottle faces the propeller shaft.

When the blade is on straight, the top of the tape should be even with the end of the strut. It might be easier to cut and tape one side at a time. Cut off the extra tape and—only cutting the tape, not the bottle--cut off the tape corners. But on the tips, just cut a tiny bit off the corners so they’re not sharp.

Hey, it’s a windmill. Don’t clock somebody.

Cut off 11” or 28cm of rubber strip. Teflon scissors work best.

Tying is easy, but confusing the first time. It’s like the simplest overhand knot —just make a loop and put the end through. But we put the two ends together and treat them like one strand. Make a loop and go through. Pull a little tighter. Now we need to move the knot to the end. Hold inside the loop, right next to the knot, and pull. The knot actually moves toward the end. This does not work with regular rubber bands, but this special stuff for model airplanes is amazing.

Plastic straws are available everywhere, so we’ll use them for the fuselage. But foam grocery trays also work great, so we’ll look at that kind of fuselage too.

Mark and cut two straws to length. It’s ok to have a bit of the bendy part at the end. Tape together at both ends.

If I just glued the propeller bearing on like this, the spinning rubber band hook would hit the fuselage. We need a spacer, so mark one centimeter on the leftover swap stick but don’t cut it yet. Lay down about a cm of hot glue. The trick for getting enough strength is spreading around a layer of hot glue, but just a thin layer. Cut off flush with the straws. Now glue on the propeller assembly. Again, big blobs of glue are not good, but a thin layer, spread around, is strong. It’s easy to get glue on the shaft. Pull it off if that happens. And get rid of those pesky little hairs of glue. Your propeller should turn freely.

The hook for the other end of the rubber band has to be on the same side as the front hook. It should slant out a little so the rubber stays on. I used to glue it all the way across the back, like this. But if you might experiment with making an airplane, then it’s good to have this other straw not glued. That makes it easy to attach a tail section here. So now I only glue the hook into this straw. You can cut off the extra.

The knot always goes in the back. A bit of something soapy or shampoo to the hub reduces friction.

If you try to fly the helicopter now, the fuselage spins instead of the propeller. Let’s start with an easy, reliable wing out of a quarter sheet of printer paper, so we can get in the air. Then you might want to experiment with other, even more efficient wings. If the paper doesn’t quite fit in between the straws, cut a little off. You can cut the top corners to make it more streamlined. You might or might not need a piece of tape. And you can even improve the efficiency of the paper wing by folding flaps that counter-rotate against fuselage spinning. And of course you can decorate.

One of the things I like this project is everybody gets into the air with a really good flying machine. Then, for people who just gotta make it better, there’s a lot of exploring to be done to find the best wing design. I don’t know what the best wing is; I hope you let me know what your experiments turn up. Here’s what my experiments have found so far.

The farther out the wings extend, the more effective they are at keeping the fuselage from spinning—because of the leverage that the wingtips have. That’s where the Dragonfly name came from. Paper is not stiff enough when it’s long, so let’s try some cardboard. Well, not so good. Let’s weigh the cardboard wing: about 4 grams. That doesn’t seem very heavy, but I think we need to compare it with other things. How much do the old paper wings weigh? About 1 gram. And how much does the rest of the helicopter weigh? So the fuselage, propeller and rubber band combined still weigh less than a cardboard wing. Mystery solved: the cardboard is heavy.

I’m not saying that you need a triple beam balance, but let’s keep in mind that weight is really important. How about a wing from a foam plate? Get the cheapest kind because they weigh a little less. Cut and taped together to a long wing shape, it weighs less than cardboard and flies pretty well.

I tried making a foam wing from and egg package. It feels perceptibly thicker than plate foam and weighs more.

Still more variables to experiment with: the width and length of the wing. Like the paper wing, keeping a foam wing short might not be the highest performance—but it’s not bad—and it’s stable and reliable.

Where a long wing is on the fuselage can make a huge difference in flight stability. I find that near the middle gives more stable flight.

Slanting the wings—called dihedral—can also affect flight stability, and it seems to matter sometimes if the concave side faces toward or away from the rubber band.

I’ve discovered that if I twist each wing like this, I get auto-gyrating returns to earth, as well as better counter-rotation. Actually splitting the wings to resemble dragonflies more does not seem to affect flight.

What about making bat wings out of bamboo and tissue paper? There are lots of wing designs waiting to be invented.

Using soap or special lubricants can allow you to wind up more; as can using special winding devices.

You can even do crazy things like send up simple paper, time-release gliders—pushed out by the unwinding rubber band.

A propeller that’s not balanced will shake the helicopter. You can tell which end is heavier because it will always go down when you take off the rubber band. I prefer to make the other end heavier by adding tape, although I’ve heard of people cutting the heavy end of the propeller.

Foam plates, egg and grocery packages are made from extruded polystyrene XPS. The surface is smooth, without texture. But you’ve probably also seen expanded polystyrene, EPS foam, in packaging. You know it by the circles. EPS is less dense than XPS. This wing from EPS foam only weighs an astonishing .2 grams and goes higher than any other wing. But you have to cut it into thin sheets about 2mm or a bit less thick. That’s easy to do with a hotwire foam cutter. Making a hotwire foam cutter is not difficult; it runs off a common car battery charger or car battery; and nickel-chromium resistance hotwire is very inexpensive. As an added bonus, once you can slice your own foam wings, you can try cutting even thinner foam paper for walkalong gliders. These gliders are so light that you can levitate them like magic. You’re actually surfing them on an invisible wave of deflected air! I have a feeling that if you like flight projects like helicopters, you might also get a kick out of walkalong gliders. Check out the video description for more information.

I like to hear from people who are making the dragonfly helicopters--both if they fly great or if you are having trouble. In fact, if you are having a difficult time, I can help you figure it out, and that helps me understand how to make my instructions better.

I really like fuselages made from grocery packaging. They’re a little lighter than straws. But they are not available everywhere. And either you have to find one that’s thick enough, or tape two together. There’s a cool trick of using the side to make that spacer that allows the hook to rotate freely.

The back hook for the rubber band is easy, too.

Well that’s about it, but stay in touch. Subscribe and ring the bell if you like this kind of project. Lots more DIY science projects at sciencetoymaker.org.