Popguns are loud and fun. I have made the assumption that a person who can build this popgun is smart enough to know that you don't shoot at people.

Some people who built this project suggested variations, which I have included at the bottom of the page.

What You Need

- One foot of 1/2" diameter PVC plastic pipe

The pipe forms the outside of the popgun. Some hardware stores might sell it by the foot. From other places, like building centers, you will have to buy 5 or 10 feet at a time. It is still little more than a dollar for all 10 feet. PVC pipe is white. Do not get "CPVC" pipe, which is more expensive and a tanish color. One more confusing thing: even on the inside, 1/2" diameter pipe is actually bigger than 1/2" diameter. Go by what the writing says on the outside of the pipe, not by actually measuring. - 1/2" diameter wooden dowel

The dowel is for making the plunger, which you push into the pipe to compress the air. Also available from hardware stores and building centers, it comes in either 3 foot or 4 foot long pieces. You can get material for 2 popguns out of a 3' dowel or for 3 popguns out of a 4' dowel - Foam meat/vegetable packaging tray

This is for the plunger seal. Meat, poultry, small fruits and vegetables are put on these trays in the grocery store and wrapped in clear plastic. See the bottom of the page for a substitute. - 1" long (or the shortest available) drywall screw

The drywall screw holds the seal to the tip of the plunger. Hardware stores and building centers with bulk, unpackaged screws will let you get just the one that you need, instead of having to buy a box of them. The shorter it is, the easier it is to screw in. - Tape

Duct tape or electrical tape works best. You could use masking tape. Clear tape is the least satisfactory, but ok in a pinch. - Strong string, hacksaw blade, phillips-head screwdriver, scissors

The scissors should be adult size, not kid sized. You can use a hacksaw or just the cheap blade without the frame. - Either a cork or a small piece of 1" to 2" thick styrofoam insulation

Alas, natural corks are getting harder to find, and the synthetic rubber ones don't work. Ask around, though. You can easily make a substitute that is just as good if you get a small piece of "closed-cell" styrofoam anywhere from 3/4" to 2" thick. Most people, even at a building center, won't know what you mean by"closed-cell." Instead, refer to it as the kind of styrofoam used for basement foundations under grade (underground). It's usually light blue or pink. Unfortunately, the white "bead board" foam used to package electronic equipment does not work well.Styrofoam is sold in sheets big enough to make several thousand corks. Usually building supply/lumber yards sell damaged/ broken pieces cheap. If that doesn't pan out, do you have any relatives, friends or neighbors who might have some left over from a construction project? Finally, someone at a construction site might give you a scrap, especially if you make the rest of popgun and show them how it works. Once you are aware of it, closed-cell foam is quite ubiquitous

Step1 Cut the dowel and the PVC pipe.

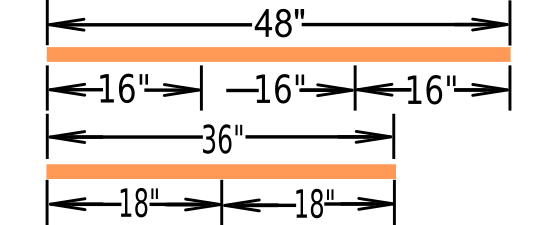

If your wood dowel is 3' (36") long, cut into two 18" pieces. If your dowel is 4' long (48") you can cut it into three 16" pieces if you're making three popguns. Use a hacksaw, or even just a hacksaw blade to cut it.

If your wood dowel is 3' (36") long, cut into two 18" pieces. If your dowel is 4' long (48") you can cut it into three 16" pieces if you're making three popguns. Use a hacksaw, or even just a hacksaw blade to cut it.

Again with a hacksaw blade, cut a 1' (12") piece of PVC pipe. Make the cut as straight as possible.

Step 2 Bevel the inside corner of pipe on one end.

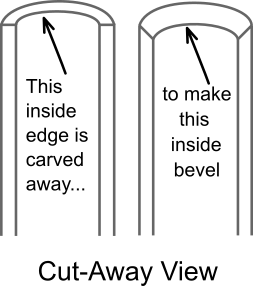

This will probably be the hardest to understand step, although once you know how to do it, it will only take a minute to do. Beveling the inside allows us to punch out perfectly sized seals (in step 3), punch out substitute "corks", and the slanting inside wall lets you get big corks in the popgun that would otherwise get stuck on the inside edge.

This will probably be the hardest to understand step, although once you know how to do it, it will only take a minute to do. Beveling the inside allows us to punch out perfectly sized seals (in step 3), punch out substitute "corks", and the slanting inside wall lets you get big corks in the popgun that would otherwise get stuck on the inside edge.

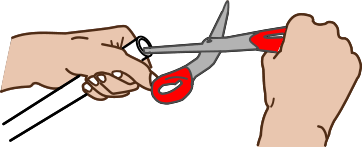

We will use half of a pair of scissors to shave off the inside corner. That does not mean we will take the scissors apart. It just means we'll use one of the pieces like a knife. I will refer to the one part we use as a scissor (singular) from now on. Why not simply use a knife? Knives that are thin enough to fit inside the pipe usually flex too much and they are sharpened at an angle that gets stuck in the plastic. Scissors, on the other hand, are narrow, rigid, and sharpened to a much more obtuse angle which shaves plastic without getting stuck.

We will use half of a pair of scissors to shave off the inside corner. That does not mean we will take the scissors apart. It just means we'll use one of the pieces like a knife. I will refer to the one part we use as a scissor (singular) from now on. Why not simply use a knife? Knives that are thin enough to fit inside the pipe usually flex too much and they are sharpened at an angle that gets stuck in the plastic. Scissors, on the other hand, are narrow, rigid, and sharpened to a much more obtuse angle which shaves plastic without getting stuck.

Before starting, wrap about 6" of tape around the first 1/2" inch of one of the scissor points. You will be levering the scissor against the pipe wall. If you don't wrap up the point, it will tear up the inside of the pipe, which will cause air leakage. Note that you will using the the scissor as a "second class lever" (more about levers in the "Exploring Popguns" page). With the taped point jammed against the inside wall, and your hand exerting force on the handle, you can multiply the force to the part of the scissor that is shaving down the inside edge.

Before starting, wrap about 6" of tape around the first 1/2" inch of one of the scissor points. You will be levering the scissor against the pipe wall. If you don't wrap up the point, it will tear up the inside of the pipe, which will cause air leakage. Note that you will using the the scissor as a "second class lever" (more about levers in the "Exploring Popguns" page). With the taped point jammed against the inside wall, and your hand exerting force on the handle, you can multiply the force to the part of the scissor that is shaving down the inside edge.

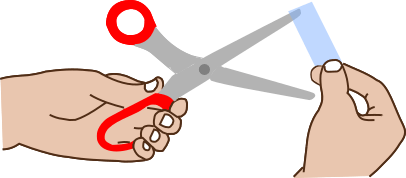

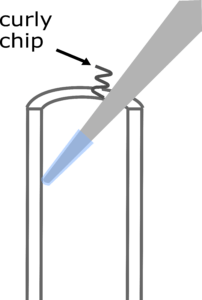

When you have looked at all the text and illustrations in Step 2 and you have some idea of what you need to do, push the taped-up point a bit into the pipe, and see if you can start scraping away a bit of the inside edge with the sharp edge of the scissors. The taped tip might slip around. Keep working with it. You know you're starting to get it when you see little curly bits of plastic in front of the edge. People who machine metals and plastics call that curl a "chip."

Continue shaving away the inside edge until the inside is beveled to the outside edge.

Step 3 Punch out seals and assemble the plunger..

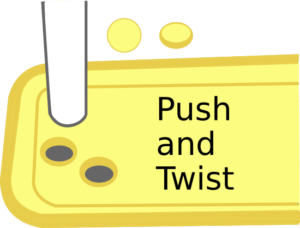

Using the beveled end of the pipe, it should be easy to punch circles out of the foam packaging tray. These will be the seals which keep air from leaking out of the pipe. Put the foam tray on a table and push the pipe down on it while at the same time twisting it. You need 3 circles.

Using the beveled end of the pipe, it should be easy to punch circles out of the foam packaging tray. These will be the seals which keep air from leaking out of the pipe. Put the foam tray on a table and push the pipe down on it while at the same time twisting it. You need 3 circles.

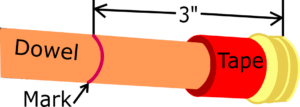

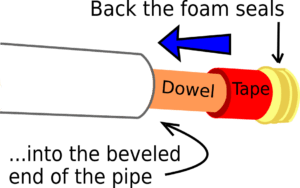

Wrap tape (red in the illustration) around one end of a dowel, with the edge of the tape flush with the edge of the dowel. Put as many wraps of tape as you can and yet still fit easily inside the pipe. The illustration shows electrical tape. If you use duct tape it will be wider.

Wrap tape (red in the illustration) around one end of a dowel, with the edge of the tape flush with the edge of the dowel. Put as many wraps of tape as you can and yet still fit easily inside the pipe. The illustration shows electrical tape. If you use duct tape it will be wider.

The tape wrap does two things: First, it keeps the dowel end from splitting open (or holds it together if it does) when we do the next thing: screw the drywall screw into the end of the dowel. Second, it backs up the seals in case the high-pressure air would blow them out.

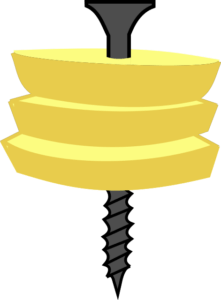

Screw the drywall screw into the centers of the three round, foam seals.

On the same end of the dowel you just wrapped the tape, screw the drywall screw into the center end of the end of the dowel. You might want to tap the screw in a little with a hammer to get it started. Rubbing a little soap or fat on the threads of the screw make a little easier to screw in. Twist the screw in until it makes the first foam seal indent a little.

On the same end of the dowel you just wrapped the tape, screw the drywall screw into the center end of the end of the dowel. You might want to tap the screw in a little with a hammer to get it started. Rubbing a little soap or fat on the threads of the screw make a little easier to screw in. Twist the screw in until it makes the first foam seal indent a little.

Step 4 Finish the pop gun

You could say that the popgun is finished at this point, but trust me: spending a few minutes to keep the dowel from pulling out the back all the time is well worth the effort. We will use string and tape to make sure that about 3" of the plunger stays in the pipe.

You could say that the popgun is finished at this point, but trust me: spending a few minutes to keep the dowel from pulling out the back all the time is well worth the effort. We will use string and tape to make sure that about 3" of the plunger stays in the pipe.

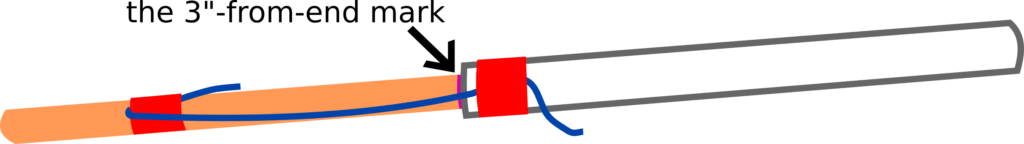

Start by making a mark on the plunger 3" from the end with the foam seals. Next, put the end of the dowel without seals into the beveled end of the pipe. When the dowel comes out the other end of the pipe, pull the seals just into the pipe, but no further in.

Start by making a mark on the plunger 3" from the end with the foam seals. Next, put the end of the dowel without seals into the beveled end of the pipe. When the dowel comes out the other end of the pipe, pull the seals just into the pipe, but no further in.

Important: Never push the seals into the pipe because they will get wrecked. Always pull them in.

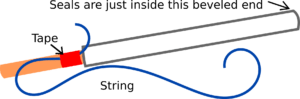

With the seals still just inside the pipe, tape a piece of string to the dowel, right next to the other end of the pipe. Tape near the end of the string, but let a couple of inches of string hang out. Don't worry about the tape being wider than in the illustration if you use duct tape.

With the seals still just inside the pipe, tape a piece of string to the dowel, right next to the other end of the pipe. Tape near the end of the string, but let a couple of inches of string hang out. Don't worry about the tape being wider than in the illustration if you use duct tape.

Now we are going to tape the other end of the string to the pipe so the dowel cannot come all the way out. Pull the dowel out until you get to the mark you made 3" from the end. While keeping that position, tape the other end of the string to the pipe, making sure the string is tight. Once again, there should be a couple of inches of string hanging out from the tape.

Now we are going to tape the other end of the string to the pipe so the dowel cannot come all the way out. Pull the dowel out until you get to the mark you made 3" from the end. While keeping that position, tape the other end of the string to the pipe, making sure the string is tight. Once again, there should be a couple of inches of string hanging out from the tape.

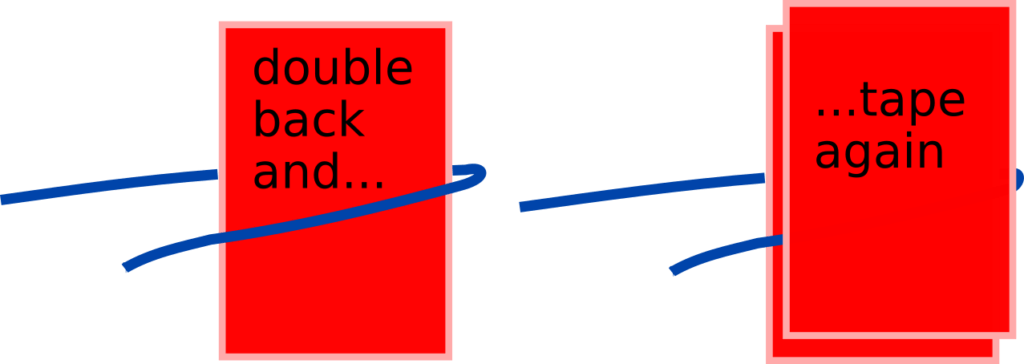

The reason we let a little bit of the string end hang out is that we are going to double it back over the tape and tape it again. This makes it very hard to pull out. Do this both where the string is taped to the dowel and to where the string is taped to the pipe. Where the string is taped to the dowel, continue wrapping tape around there until the bulge is so big that it doesn't fit into the pipe anymore. Congratulations! You have finished the popgun

The reason we let a little bit of the string end hang out is that we are going to double it back over the tape and tape it again. This makes it very hard to pull out. Do this both where the string is taped to the dowel and to where the string is taped to the pipe. Where the string is taped to the dowel, continue wrapping tape around there until the bulge is so big that it doesn't fit into the pipe anymore. Congratulations! You have finished the popgun

Step 5 Make a foam "cork."

This is easy and quick, just like when you punched out the foam seals, but with thicker pieces of foam. Remember pull the dowel out of the way and to twist the pipe of the popgun as you push it in. To get the foam out, you will have to pop the popgun. Make sure the dowel is pulled back as far as the string will let it. Then push it forward as fast as you can. Kaboom! Getting the foam back in again is easiest if you twist it while pushing it in.

This is easy and quick, just like when you punched out the foam seals, but with thicker pieces of foam. Remember pull the dowel out of the way and to twist the pipe of the popgun as you push it in. To get the foam out, you will have to pop the popgun. Make sure the dowel is pulled back as far as the string will let it. Then push it forward as fast as you can. Kaboom! Getting the foam back in again is easiest if you twist it while pushing it in.

If you already have a wine cork, you might have to bevel one end so it fits into the pipe. There are two ways to do this. You can rub the end on rough concrete or you can cut the bevel with a sharp knife. Again, you should twist it as you push it into the pipe. A tight-fitting cork is hard for young kids to pop out. You might want to consider a foam cork for them.

Feedback

From Carla Avitabile

Carla is a teen librarian with the Marin County Free Library, and ran a Maker Camp through the library. She cleverly substituted on old bicycle inner tube—lubricated with a bit of Vaseline—for the seal; where I used the foam from food packaging. I can see how that might be more durable.

From Chris Ehlers

One tip for your readers: search through copper fittings at the hardware

store. I found a T-fitting that is the perfect diameter to cut out the foam

seals (plus they are extremely cheap).

From Craig Miwa

I wanted to build some old style pop guns for my boys this weekend and used your website ideas for a basic plan and they worked out great. I made a few small changes that worked out good for me.

- I used a 1/2" PVC end cap, in which I bored a 5/8" hole for the rod

to go through. This makes the string unnecessary and keeps the kids from pulling the plunger all the way out. I've also considered putting a 'T' at the base of the PVC as an easier to hold handle for the kids. - I used some 3/8" washers around the foam plunger on the dowel. It

makes the foam act more like a o ring I think at least it keeps it a little stiffer. - This was cosmetic but I put little handles on the end of the plunger

so it was easier to hold. It also stops the kids from pushing the plunger in too deep.

Something else I might do for younger kids is tie a string on the end of the plunger and attatch it to the cork so it pops and then they just cock it back and it pulls the cork back in ready to go. This way they won't loose the cork too.